Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for Fiberglass Weave Types, Triaxial Fiberglass Fabric, Fabric For Fiberglass, Our company is dedicated to providing customers with high and stable quality products at competitive price, making every customer satisfied with our products and services.

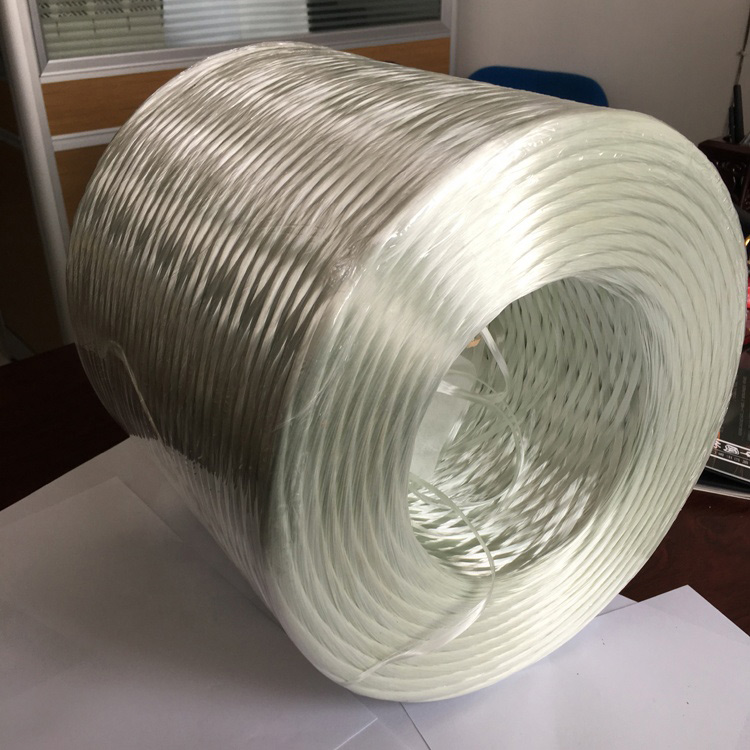

Top Suppliers Jushi Roving - Fiberglass roving for Filament winding – Yaosheng Detail:

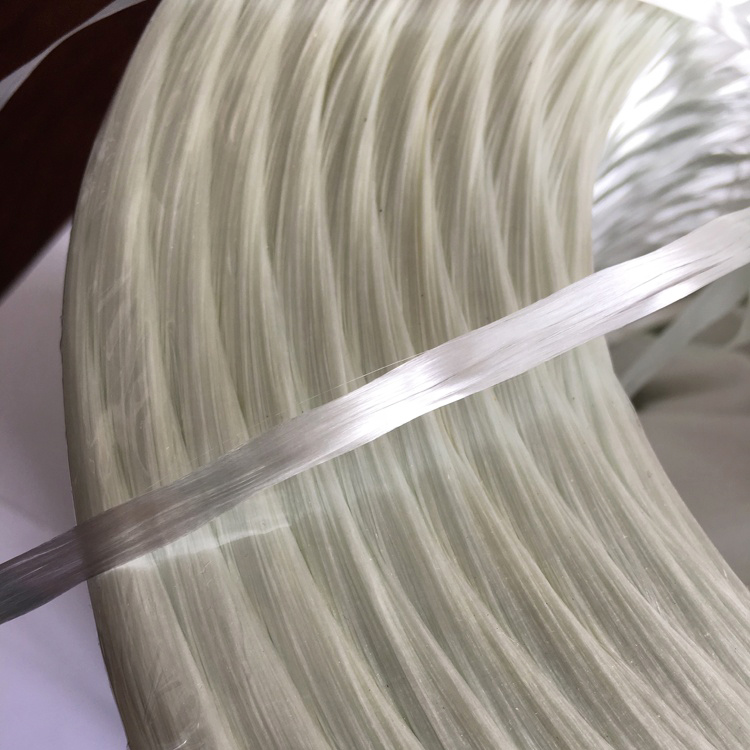

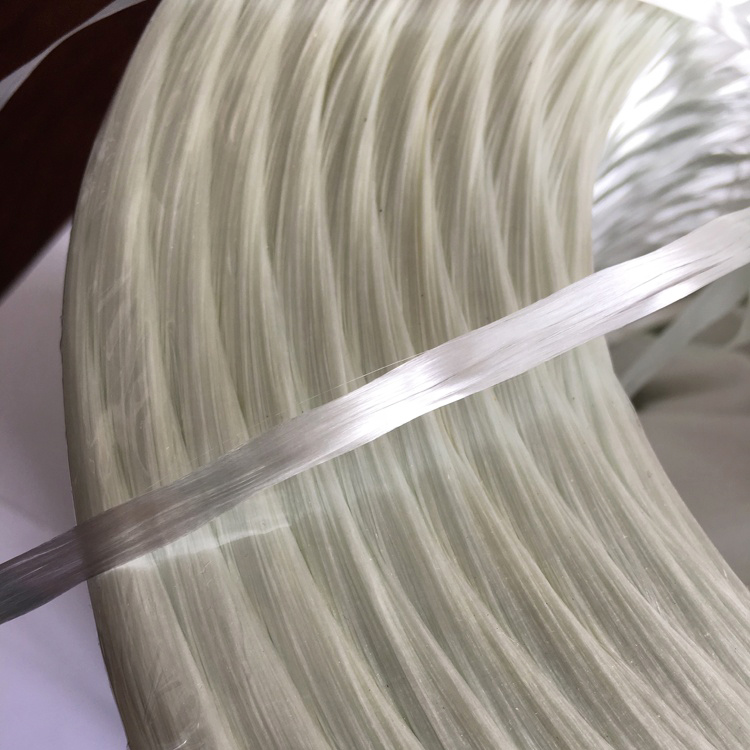

The product is an alkali-free twist-free roving. The surface of the roving is coated with silane-based sizing agent. It is compatible with unsaturated resin, epoxy resin and vinyl resin system. It can be used in amine or acid anhydride curing system and internal or external fade Type of winding process used.

The product has high mechanical strength, good electrical performance and good fatigue performance. It is mainly used in the manufacture of chemical storage tanks, reinforced thermoplastic pipes, high-tension winding process to produce small-diameter sucker rods, and winding high-pressure pipelines, pressure vessels, and high-pressure gas cylinders. , pultruded profiles, bars, boats, high-voltage fiberglass reinforced plastic pipes, hollow insulating sleeves, insulating tie rods and other ultra-high-voltage composite insulators, and are widely used in power generation, transmission and distribution and other power systems.

Product Specifications

| Model |

Roving type |

Glass type |

Sizing type |

Typical filament diameter (um) |

Typical linear density (tex) |

| ER-266 |

Assembled Roving |

E

|

Silane

|

13 |

2400 |

| EDR-306B |

Direct Roving

|

12 、13 |

735 、765 |

| EDR-308 |

17 、21 |

1100、 2000 |

| EDR-308H |

17 、21、24 |

600、1200、2000、2400、4800 |

| EDR-308S |

17 、21 、24 |

600 / 900、2400 / 4800、2000、2400、4800 |

| EDR-310S |

15、17、24 |

1100、735 / 1200、2400 |

| EDR-318 |

13、17、21、24 |

600、735、1200、1985、2100、2400、4800 |

| EDR-386H |

13、17、24、31 |

300、600、1200、2400、4800 |

| EDR-386T |

13、16、17、21、24、31 |

200、300、400、600、1200、2400、4800 |

Technical Parameters

| Model |

Moisture content(%) |

Sizing content(%) |

Breakage strength(N/tex) |

Tensile strength(MPa) |

Tensile modulus(GPa) |

Shear strength(MPa) |

| ER-266 |

≤ 0.07 |

0.55 ± 0.15 |

≥ 0.40 |

/ |

/ |

/ |

| EDR-306B |

≤ 0.10

|

0.70 ± 0.10 |

≥ 0.50 ( >12 um)

≥ 0.60 ( ≤ 12 um) |

/ |

/ |

/ |

| EDR-308 |

0.60 ± 0.10 |

≥ 0.40 |

2625.0 / 380.6 |

81.49 / 11.82 |

72.0 / 10.4 |

| EDR-308H |

0.55 ± 0.15 |

≥ 0.40 |

2675 |

82.2 |

74 |

| EDR-308S |

≥0.40 (<4800tex)

≥ 0.35 ( ≥ 4800 tex) |

2590 |

82.0 |

74.3 |

| EDR-310S |

≥ 0.40 |

2450 |

81.76 |

70.0 |

| EDR-318 |

0.55 ± 0.10 |

≥ 0.40 |

2530 |

81.14 |

70.0 |

| EDR-386H |

0.50 ± 0.15 |

≥ 0.40 (<17 um)

≥ 0.35 (18~24 um)

≥ 0.30 ( >24 um) |

2765 / 2682 |

81.76 / 81.47 |

/ |

| EDR-386T |

0.60 ± 0.10 |

≥0.40 (≤2400 tex)

≥0.35 (2401~4800 tex)

≥0.30 (>4800 tex) |

2660 / 2580 |

80.22 / 80.12 |

68.0 |

Instructions

◎The product is best used within one year after production, and should be stored in the original packaging before use, and ensure a cool and dry environment.

◎ Please avoid collision when using the product to prevent the yarn from being scratched or broken.

◎ Please pay attention to the temperature and humidity balance of the environment during storage, and can be adjusted appropriately when using.

◎ When using, please control the tension reasonably and ensure the uniformity of tension, so as to achieve the best effect of the product.

Packaging

Products are packaged in pallet + cardboard and shrink film

Storage

Under normal circumstances, fiberglass products should be stored in a dry, cool and moisture-proof environment. The best temperature and humidity in the environment should be kept at -10℃~35℃ and ≤80% respectively. For safety and to avoid product damage, pallets should not be stacked more than three layers high. When overlapping pallets, special care should be taken to move the upper pallets correctly and smoothly to prevent product from collapsing and causing losses.

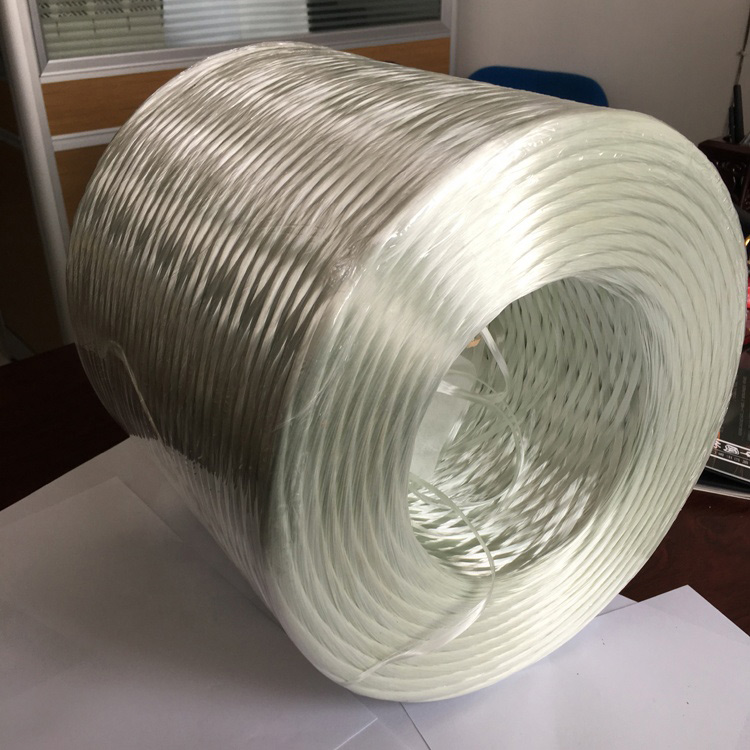

Product detail pictures:

Related Product Guide:

Our company sticks into the basic principle of "Quality is definitely the life of the business, and status may be the soul of it" for Top Suppliers Jushi Roving - Fiberglass roving for Filament winding – Yaosheng , The product will supply to all over the world, such as: French, Nepal, Florence, With the first-class solutions, excellent service, fast delivery and the best price, we've won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.