As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we’re the lowest around for Professional China Emulsion Fiberglass Chopped Strand Mat for FRP, Honesty is our principle, experienced procedure is our do the job, provider is our goal, and customers’ gratification is our future!

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we’re the lowest around for China Emulsion Chopped Strand Mat, fiberglass mat, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

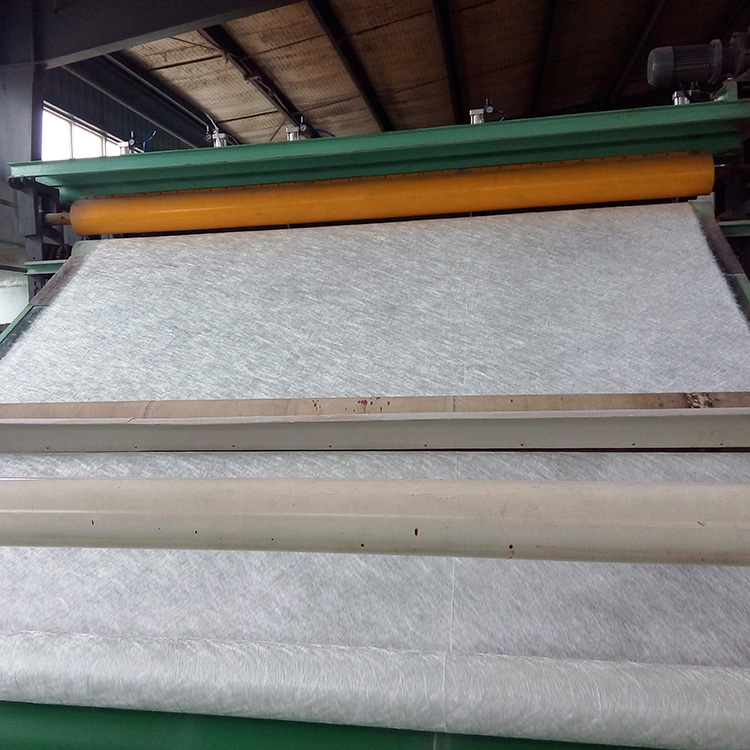

Fiberglass Mat Production Process

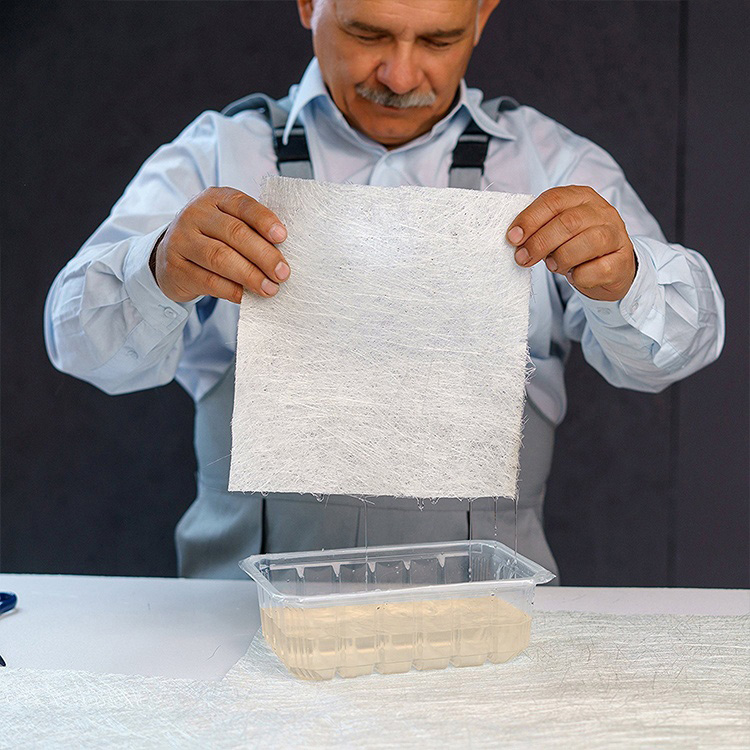

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

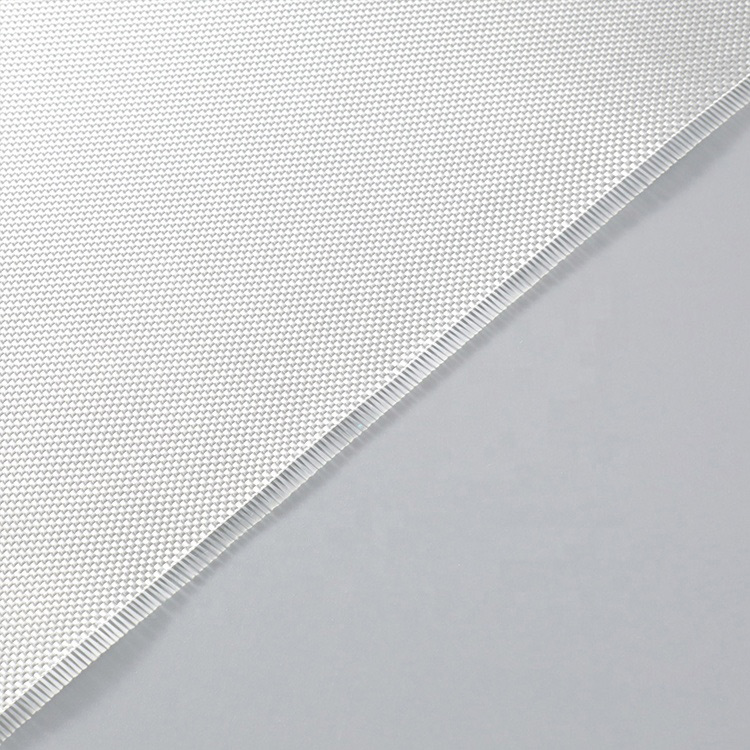

Fibreglass matting are made of randomly distributed chopped strands held together by emulsion/power binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3120mm. Special requirements may be available upon request.

Product Specifications

|

Product name

|

Type of Product

|

|

Power

|

Emulsion

|

| Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

| Fiberglass chopped strand mat |

200g |

80-100 |

2.8 – 4.8 |

≤0.1 |

200g |

70-90 |

4.2-6.2 |

≤0.2 |

| 225g |

90 -110 |

2.7 -4.7 |

≤0.1 |

225g |

75-95 |

4.1-6.1 |

≤0.2 |

| 250g |

100 – 120 |

2.6 -4.6 |

≤0.1 |

250g |

80-100 |

4.0-6.0 |

≤0.2 |

| 300g |

110-130 |

2.5-4.5 |

≤0.1 |

300g |

110-130 |

3.6-5.6 |

≤0.2 |

| 350g |

130-150 |

2.5-4.5 |

≤0.1 |

350g |

120-140 |

3.6-5.6 |

≤0.2 |

| 400g |

140-160 |

2.5-4.5 |

≤0.1 |

400g |

130-150 |

3.6-5.6 |

≤0.2 |

| 450g |

170-190 |

2.4-4.4 |

≤0.1 |

450g |

160-180 |

3.2-5.2 |

≤0.2 |

| 550g |

200-220 |

2.3-4.3 |

≤0.1 |

550g |

200-220 |

3.2-5.2 |

≤0.2 |

| 600g |

250-280 |

2.3-4.3 |

≤0.1 |

600g |

250-280 |

3.2-5.2 |

≤0.2 |

| 900g |

320-400 |

2.3-4.3 |

≤0.1 |

900g |

320-400 |

3.2-5.2 |

≤0.2 |

Product Application

The chopped strand mat are compatible with unsaturated polyester, vinyl ester and other various resins.

It’s mainly used in hand lay-up, filament winding and compression molding processes. The typical FRP products are panels, tanks, boats, complete set of sanitary equipment, automotive parts, cooling towers, pipes etc.

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we’re the lowest around for Professional China China Emulsion Fiberglass Chopped Strand Mat for FRP, Honesty is our principle, experienced procedure is our do the job, provider is our goal, and customers’ gratification is our future!

Professional China China Emulsion Chopped Strand Mat, Fiberglass Mat, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

Previous:

Width 2000mm 450GSM Fiberglass Chopped Strand Mat for FRP Panel

Next:

Factory Customized China Low Static 2400tex Fiberglass Spray up Roving