“Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for OEM Supply Power Emulsion Fiberglass Chopped Strand Mat, We believe that in good quality more than quantity. Before export of the hair there is strict top quality control check during treatment as per international good quality standards.

“Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for China Emulsion Chopped Strand Mat and Fiberglass Mat, We have been looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products’ quality, you can return within 7days with their original states.

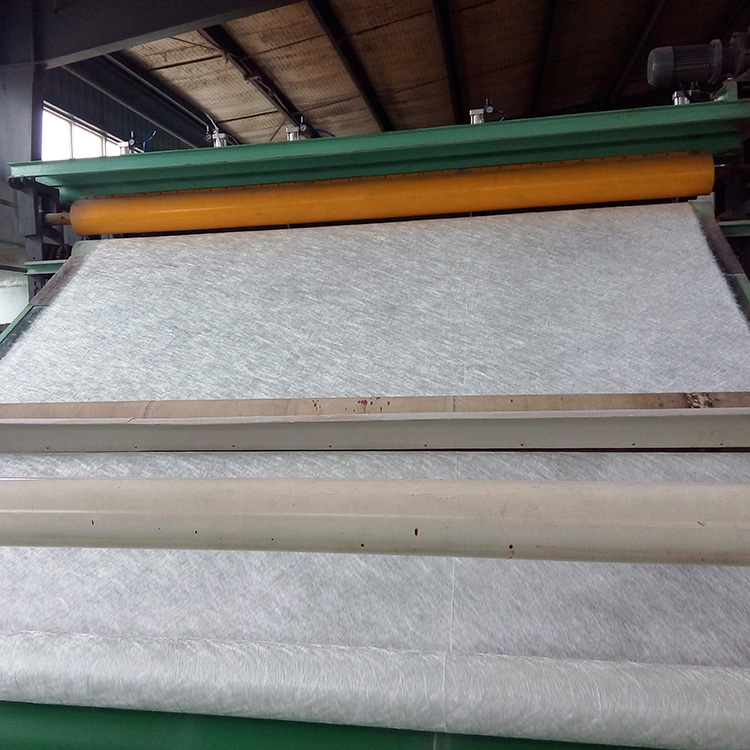

Fiberglass Mat Production Process

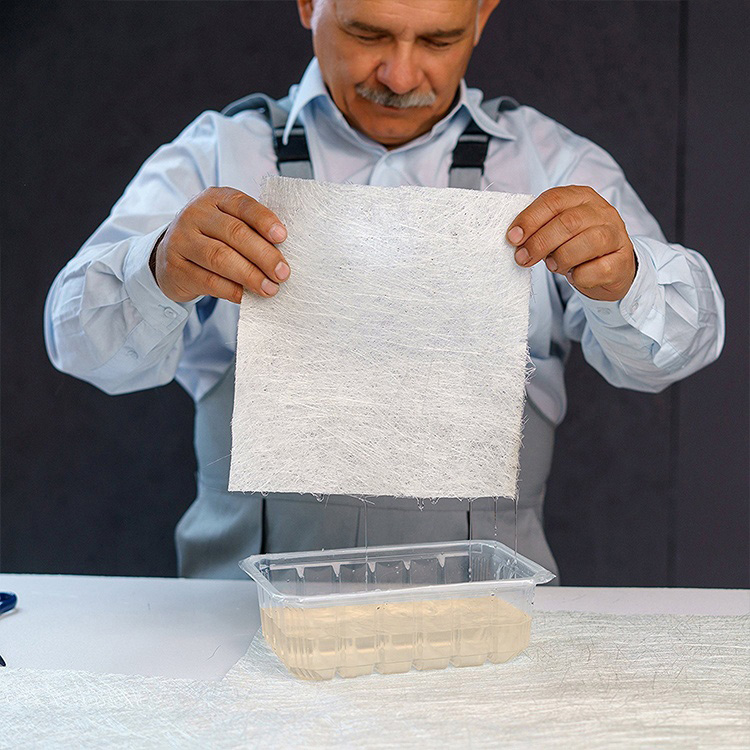

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

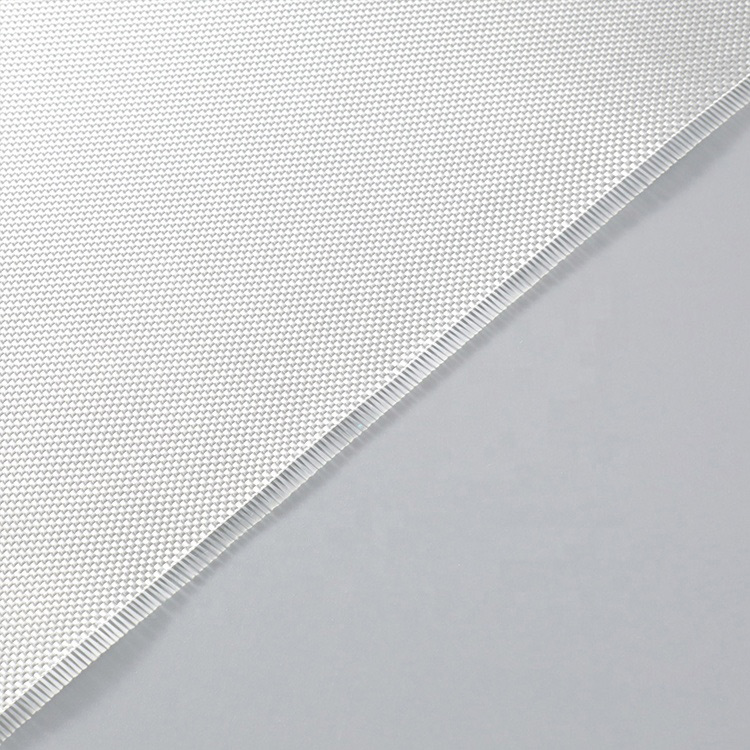

Fibreglass matting are made of randomly distributed chopped strands held together by emulsion/power binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3120mm. Special requirements may be available upon request.

Product Specifications

|

Product name

|

Type of Product

|

|

Power

|

Emulsion

|

| Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

| Fiberglass chopped strand mat |

200g |

80-100 |

2.8 – 4.8 |

≤0.1 |

200g |

70-90 |

4.2-6.2 |

≤0.2 |

| 225g |

90 -110 |

2.7 -4.7 |

≤0.1 |

225g |

75-95 |

4.1-6.1 |

≤0.2 |

| 250g |

100 – 120 |

2.6 -4.6 |

≤0.1 |

250g |

80-100 |

4.0-6.0 |

≤0.2 |

| 300g |

110-130 |

2.5-4.5 |

≤0.1 |

300g |

110-130 |

3.6-5.6 |

≤0.2 |

| 350g |

130-150 |

2.5-4.5 |

≤0.1 |

350g |

120-140 |

3.6-5.6 |

≤0.2 |

| 400g |

140-160 |

2.5-4.5 |

≤0.1 |

400g |

130-150 |

3.6-5.6 |

≤0.2 |

| 450g |

170-190 |

2.4-4.4 |

≤0.1 |

450g |

160-180 |

3.2-5.2 |

≤0.2 |

| 550g |

200-220 |

2.3-4.3 |

≤0.1 |

550g |

200-220 |

3.2-5.2 |

≤0.2 |

| 600g |

250-280 |

2.3-4.3 |

≤0.1 |

600g |

250-280 |

3.2-5.2 |

≤0.2 |

| 900g |

320-400 |

2.3-4.3 |

≤0.1 |

900g |

320-400 |

3.2-5.2 |

≤0.2 |

Product Application

The chopped strand mat are compatible with unsaturated polyester, vinyl ester and other various resins.

It’s mainly used in hand lay-up, filament winding and compression molding processes. The typical FRP products are panels, tanks, boats, complete set of sanitary equipment, automotive parts, cooling towers, pipes etc.”Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for OEM Supply Power Emulsion Fiberglass Chopped Strand Mat, We believe that in good quality more than quantity. Before export of the hair there is strict top quality control check during treatment as per international good quality standards.

OEM Supply China Emulsion Chopped Strand Mat and Fiberglass Mat, We have been looking forward to cooperating closely with you to our mutual benefits and top development. We guaranteed quality, if customers were not satisfied with the products’ quality, you can return within 7days with their original states.

Previous:

Chinese wholesale ECR Type Glass Woven Roving Cloth for Surfboard

Next:

Top Suppliers Hot Sale Reinforcement Material Fiberglass Chopped Strand Mat