abide by the contract", conforms towards the market requirement, joins during the market competition by its good quality likewise as provides additional comprehensive and great services for customers to let them turn out to be big winner. The pursue of your enterprise, is the clients' fulfillment for Chopped Strand Mat Thickness, Woven Fiberglass Cloth, 1708 Fiberglass Weight, If you are interested in any of our products or would like to discuss a customized order, please feel free to contact us.

OEM manufacturer Glass Roving - Fiberglass roving for pultrusion – Yaosheng Detail:

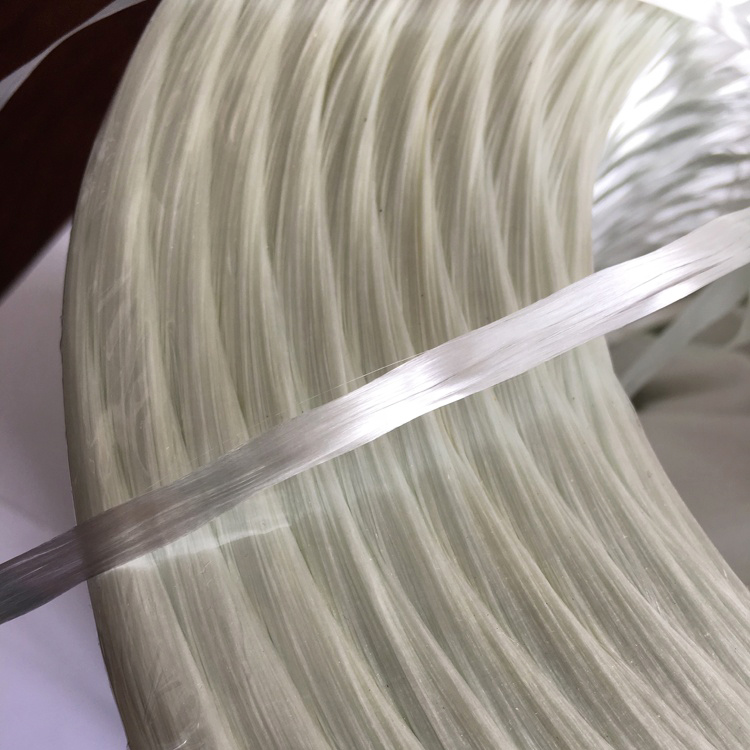

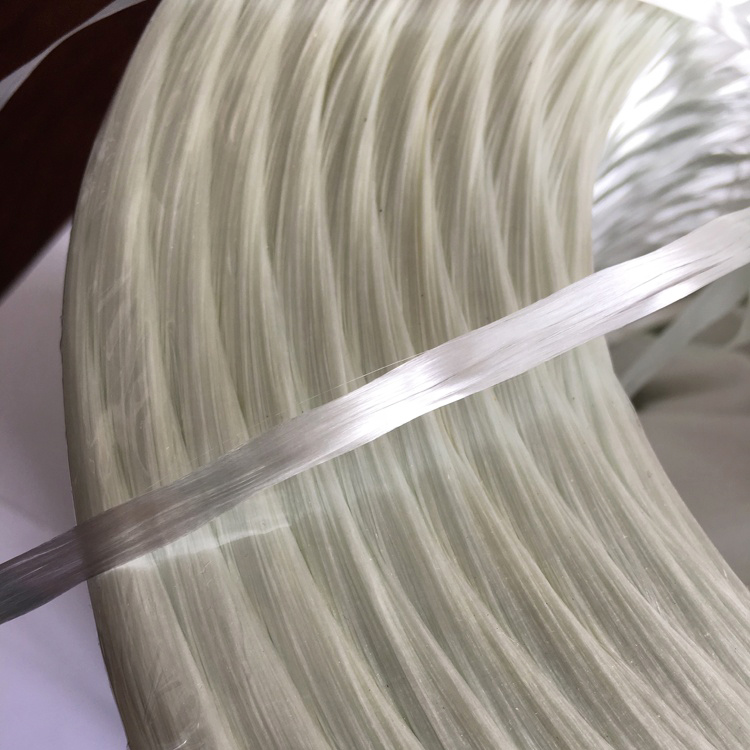

The product glass fiber roving is produced with E glass formula, which is suitable for reinforced unsaturated polyester resin, vinyl resin, epoxy resin, polyurethane resin and other thermosetting resin systems.

Has good versatility. It can be used in winding forming process, especially suitable for high-speed, high-tension pultrusion process.

Products are used in the manufacture of tent poles, outdoor travel products, pressure vessels, pipes, boats, chemical Industrial storage tanks, wind blades, geogrids, fiber optic cable reinforced cores, UHV and UHV power transmission, substation and other fields, cable trays, pultruded profiles, high-speed rail sleepers and other fields.

Specifications

| Model |

Roving type |

Glass type |

Sizing type |

Typical filament diameter (um) |

Typical linear density (tex) |

| ER-276 |

Assembled Roving

|

E

|

Silane

|

13 、16 |

2400 、4800 |

| EDR-310H |

Direct/ Assembled |

17 、24 |

1200 、2400 |

| EDR-312 |

Direct Roving |

13 、16 、24 、31 |

100、200、300、400、2400、4800 |

| EDR-312T |

17 、21 、23 、24 、31 、32 |

1200、2400、2000、4400、4800 |

| EDR-316H |

13 、17 |

300 、660 、600 、1200 |

| EDR-332 |

17 、24 、31 |

600 、1200 、2400、4800 |

| EDR-386H |

13 、17 、24、31 |

300、600、1200、2400、4800 |

| EDR-386T |

13、16、17、21、24、31 |

200、300、400、600、1200、2400、4800 |

Technical Parameters

| Model |

Moisture content(%) |

Sizing content(%) |

Breakage strength(N/tex) |

Tensile strength(MPa) |

Tensile modulus(GPa) |

Shear strength(MPa) |

Bending strength(MPa) |

Bending modulus(GPa) |

| ER-276 |

≤ 0.07

|

0.55 ± 0.15 |

≥ 0.40 |

/ |

/ |

/ |

/ |

/ |

| EDR-310H |

≤ 0.10 |

0.55 ± 0.10 |

≥ 0.40 (<4800 tex)

≥ 0.30 ( ≥ 4800 tex) |

2316 |

81.2 |

/ |

/ |

/ |

| EDR-312 |

≤ 0.10 |

0.60 ± 0.15 |

≥ 0.40 ( ≤ 4400 tex)

≥ 0.30 ( >4400 tex) |

2513 |

82.0 |

67 |

/ |

/ |

| EDR-312T |

≤ 0.10 |

0.58 ± 0.10

0.70 ± 0.15 (17600 tex) |

≥ 0.40 ( ≤ 4400 tex)

≥ 0.30 (4401~9600 tex)

≥ 0.25 ( >9600 tex) |

2265 |

81.17 |

/ |

/ |

/ |

| EDR-316H |

≤ 0.10 |

0.40 ± 0.10 |

≥ 0.40 |

2453 |

82.0 |

/ |

/ |

/ |

| EDR-332 |

≤ 0.10 |

0.45 ± 0.15 |

≥ 0.40 (<4800 tex)

≥ 0.35 ( ≥ 4800 tex) |

/ |

/ |

/ |

1400 |

50 |

| EDR-386H |

≤ 0.10 |

0.50 ± 0.15 |

≥ 0.40 (<17 um)

≥0.35 (18~24 um)

≥ 0.30 ( >24 um) |

2765 / 2682 |

81.76 / 81.47 |

/ |

/ |

/ |

| EDR-386T |

≤ 0.10 |

0.60 ± 0.10 |

≥ 0.40 ( ≤ 2400 tex)

≥ 0.35 (2401~4800 tex)

≥ 0.30 ( >4800 tex) |

2660 / 2580 |

80.22 / 80.12 |

68.0 |

/ |

/ |

Instructions

◎ It should be stored in the original packaging before use. This product is best used within 12 months.

◎ When using the product, pay attention to avoid product damage, rubbing, etc.

◎ Properly control the ambient temperature and humidity during use, and adjust the temperature and humidity of the yarn before use to balance the ambient temperature and humidity.

◎ Please control the tension reasonably and ensure the uniformity of tension when using.

Packaging

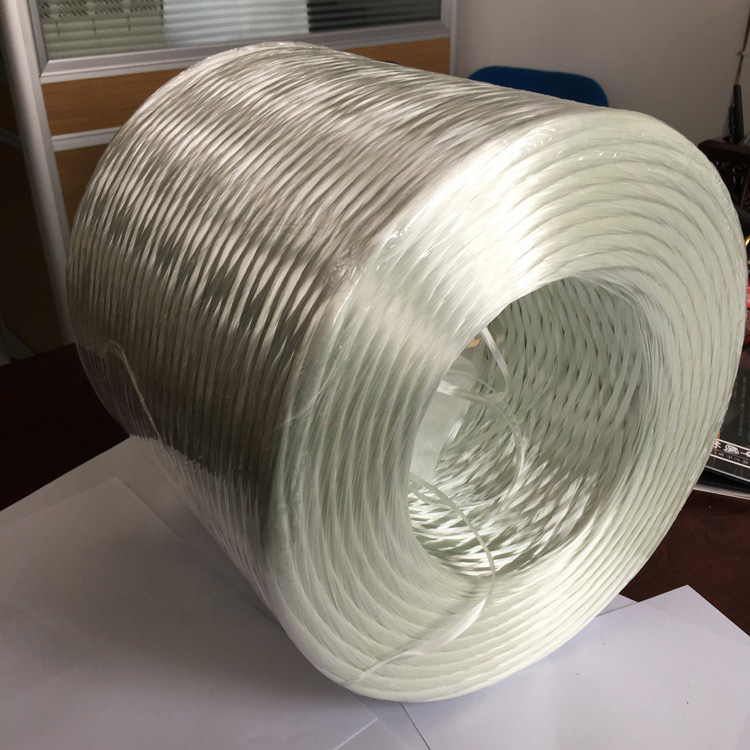

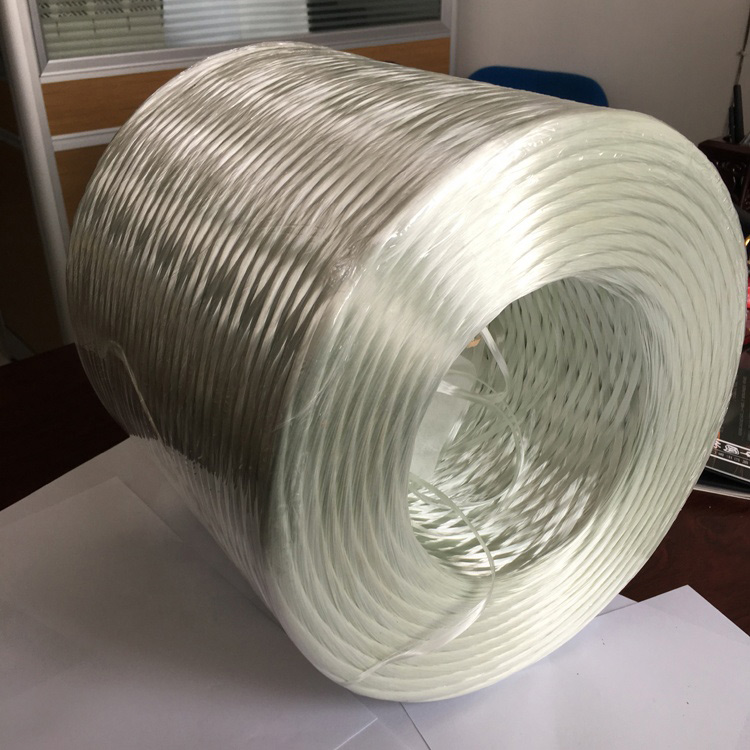

Glass fiber roving products are packed in wooden pallets, the middle layer is separated by cardboard to prevent the product from being squeezed, and shrink film is used, and the outermost layer is packed with stretch film.

Storage

The best storage conditions for this product are -10℃~35℃, relative humidity ≤80%. To ensure safety, product pallets should not be stacked more than three layers. Please move the upper pallets correctly and smoothly when stacking.

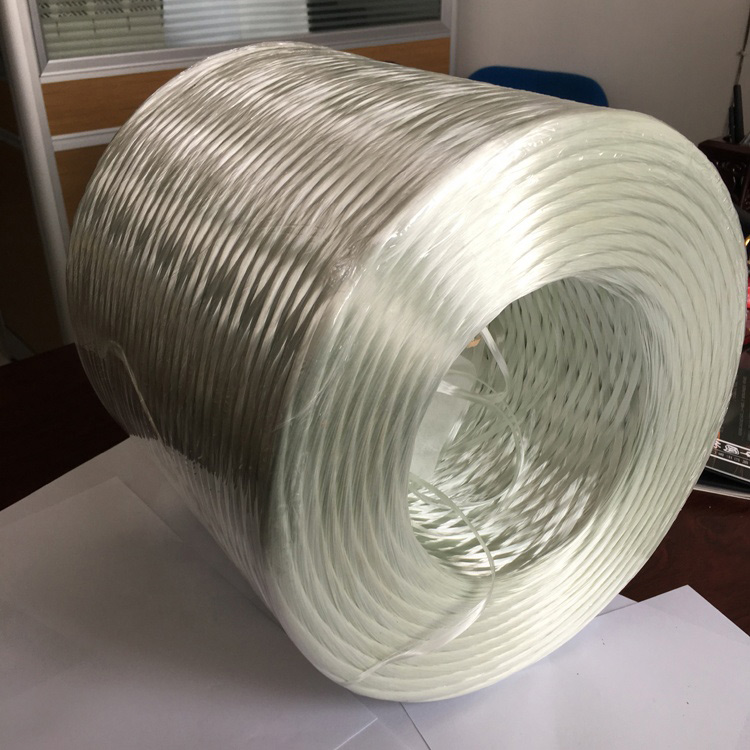

Product detail pictures:

Related Product Guide:

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for OEM manufacturer Glass Roving - Fiberglass roving for pultrusion – Yaosheng , The product will supply to all over the world, such as: Mexico, Chile, Greek, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.