Marine composite materials, especially composite materials applied to hull structures, are mainly polymer-based composite materials. According to the structure, they can be divided into two types: laminate (fiber-reinforced composite material) and sandwich structure composite material, including three aspects The important composites: reinforcement materials, resin (ie matrix) and core material.

According to the different bearing positions, it can be divided into: main bearing structure, secondary bearing structure, non-bearing structure, etc. According to the function, it can be divided into five series of materials: structure, damping, acoustics (including sound absorption, sound insulation, sound transmission), stealth (including wave absorption, wave transmission, reflection, frequency selection), and protection.

The superiority of performance is mainly reflected in: light weight and high strength, which can effectively improve the reserve buoyancy of the hull; the structure and function are integrated, and the performance can be designed under the condition of meeting the structural load, usually with acoustics, radar, vibration reduction, protection, low magnetic, etc. For other properties, the general material forming process is also the structure forming process; corrosion resistance can meet the harsh marine environment requirements such as high salt, high humidity, and ultraviolet rays; aging resistance can meet the long life requirements of ships.

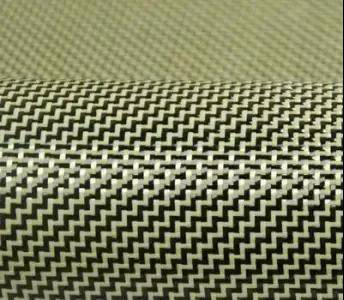

At present, carbon fiber composite materials have been widely used in aerospace, sports and leisure, automotive industry, environmental energy, civil engineering and other fields. Its application range is almost everywhere. Among them, in the fields of boats, yachts, large ships and other ships, carbon fiber The application is making progress. Carbon fiber is an ideal material for ships, because it can reduce hull vibration and maintain a good wireless communication environment between ships.

In addition, the most important reason for using carbon fiber is that this material can improve the speed and fuel economy of ships by reducing weight. For example, by using carbon fiber reinforced composite material (CFRP) to replace glass fiber composite material (GFRP), the weight of the hull can be reduced.

The application of carbon fiber and its composite materials in yachts can further reduce the weight and improve the stability of the ship by using CFRP in the superstructure and deck equipment; carbon fiber drive shafts can also reduce weight and reduce vibration; carbon fiber in the propeller blades There is also potential for a wide range of applications.

When considering the cost in boat manufacturing, under the premise of meeting the design requirements, a design method of using hybrid fiber composite materials appeared. The mixed use of multiple fiber reinforced materials overcomes some shortcomings of single fiber composite materials, improves physical and mechanical properties, and further enhances the designability of materials. The two-dimensional and three-dimensional fabrics formed by reinforcing materials can be manufactured according to design needs to meet the strength, intra-layer and inter-layer performance of ships, and further realize the requirements of light weight and high strength of ships

Deyang Yaosheng Composite Material Co., Ltd. is a professional glass fiber manufacturer, which can customize various glass fiber cloth and other glass fiber products according to customer needs. It is your trusted supplier.

E-mail: yaoshengfiberglass@gmail.com

Whatsapp: +86 15283895376

Post time: Mar-07-2022