Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for New Delivery for China 300tex-2400tex Fiberglass Roving / Direct Roving Glass Fiber Yran for Weaving, For even more data, please do not be reluctant to call us. All inquiries from you may be highly appreciated.

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for China Fiberglass Roving, Direct Roving, Strong infrastructure is the want of any organization. We’ve been backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our merchandise worldwide. To maintain smooth work flow, we’ve got sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we’re able to accomplish voluminous production without compromising on the quality.

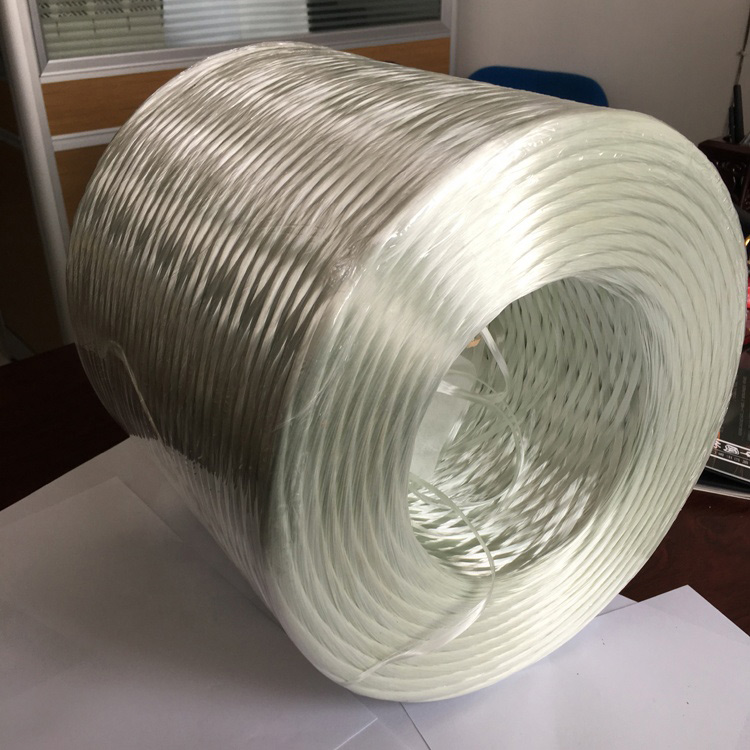

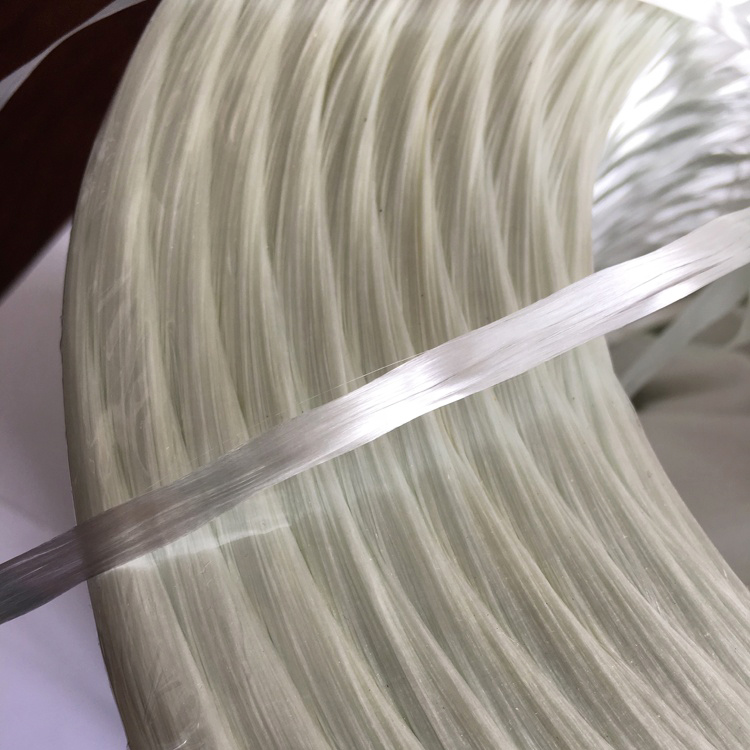

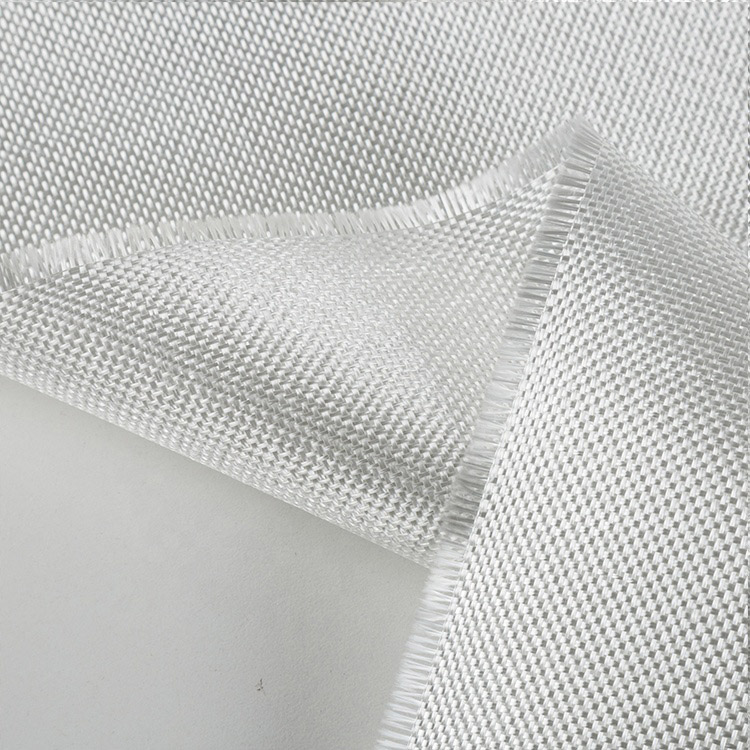

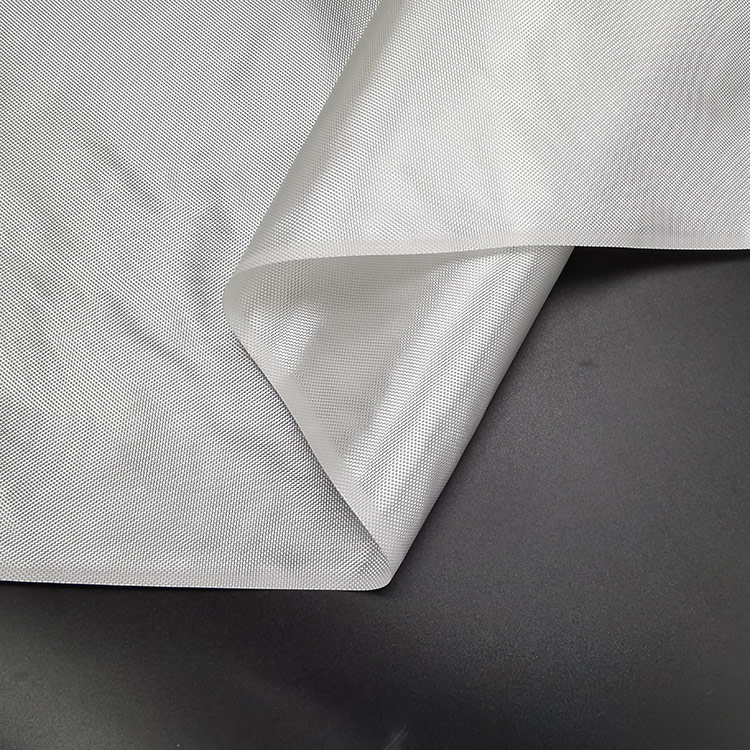

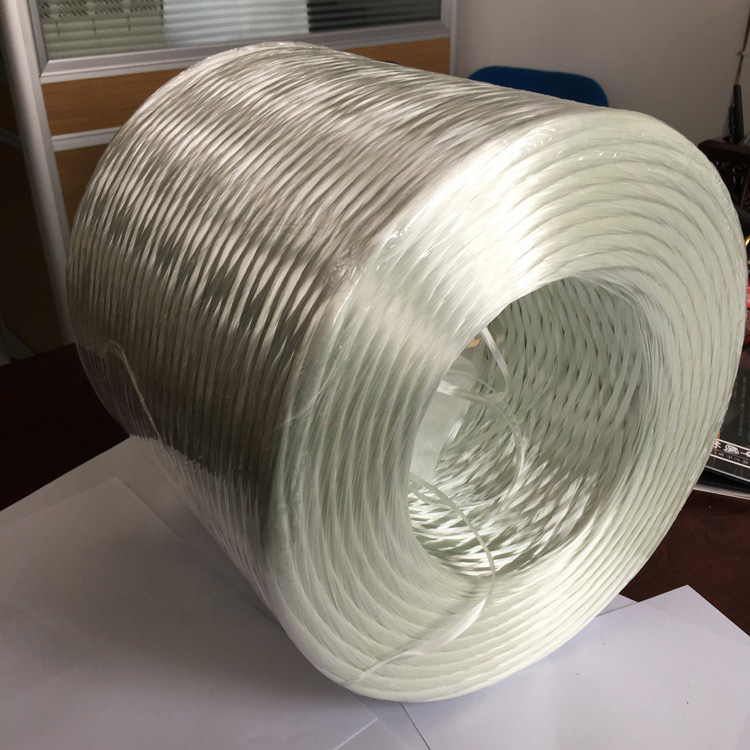

This product is an alkali-free continuous single-strand direct roving, and the surface is coated with silane-based sizing agent. It is suitable for reinforcing unsaturated polyester resin, vinyl resin, epoxy resin and polyurethane resin. It can be used for winding, pultrusion, weaving, etc. application process.

The products are suitable for manufacturing FRP pipes, pressure vessels, profiles, and fabrics for manufacturing ships, chemical storage tanks, geogrids, etc. It is also suitable for the production of cables and reinforced core materials of optical cables by pultrusion process, the manufacture of large wind power blades and yachts by vacuum-assisted resin infusion molding process, and the production of utility poles, container door panels and other products by winding or pultrusion process.

Specifications

| Model |

Glass type |

Sizing type |

Typical filament diameter (um) |

Typical linear density (tex) |

| EDR-312 |

E

|

Silane

|

13 、16 、24、 31 |

100、200、300、400、2400、4800 |

| EDR-302 |

22 、24 |

2200、4400、2400、4800 |

| EDR-306A |

17、20、21、24 |

1200、1500、1700、2400、4800 |

| EDR-320 |

17、20、22、24 |

600、1200、2400 |

| EDR-380 |

13、16、17、24 |

300、200、4800、600、1200、2400 |

| EDR-386H |

13、17、24、31 |

300、600、1200、2400、2400、4800、9600 |

| EDR-386T |

13 、16 、17 、21 、24 、31 |

200、300、400、600、1200、2400、4800 |

| EDR-390 |

13 、16、 17、 24 |

100、300、200、600、1200、1530、2400、4800 |

| EDR-396 |

13/14 、17 |

300、600、1200、2400 |

| EDR-398 |

17 |

600 、1200 、2400 |

Technical Parameters

| Model |

Moisture content(%) |

Sizing content(%) |

Breakage strength(N/tex) |

Tensile strength(MPa) |

Tensile modulus(GPa) |

Shear strength(MPa) |

| EDR-312 |

≤ 0.10

|

0.60 ± 0.15 |

≥ 0.40 ( ≤ 4400 tex)

≥ 0.30 ( >4400 tex) |

2513 |

82.0 |

67 |

| EDR-302 |

0.50 ± 0.15 |

≥ 0.35 |

2536 |

79.13 |

/ |

| EDR-306A |

0.60 ± 0.10 |

≥ 0.40 ( ≥ 4400 tex)

≥0.45 (1700~4399 tex)

≥ 0.50 ( <1700 tex) |

2732 / 2657 |

80.1 / 81.1 |

67.0 |

| EDR-320 |

0.45 ~ 0.70 |

≥ 0.40 |

2315.3 / 2488.4 |

82.5 / 82.8 |

/ |

| EDR-380 |

0.55 ± 0.15 |

≥ 0.40 |

2612 |

81.15 |

73.0 |

| EDR-386H |

0.50 ± 0.15 |

≥0.40 (<17 um)

≥0.35 (18~24 um)

≥ 0.30 (>24 um) |

2765 / 2682 |

81.76 / 81.47 |

/ |

| EDR-386T |

0.60 ± 0.10 |

≥0.40 (≤2400 tex)

≥0.35 (2401~4800 tex)

≥0.30 (>4800 tex) |

2660 / 2580 |

80.22 / 80.12 |

68.0 |

| EDR-390 |

0.55 ± 0.15 |

≥ 0.40 |

2595 |

81.9 |

74.0 |

| EDR-396 |

0.48 ± 0.10 |

≥ 0.40 |

2471 |

81.324 |

67 |

| EDR-398 |

0.55 ± 0.10 |

≥ 0.40 |

2540 |

81.95 |

71.0 |

Instructions

● The product is best used within 12 months after production, and should be kept in the original package before use.

● Care should be taken when using the product to prevent it from being scratched or damaged.

● The temperature and humidity of the product should be conditioned to be close or equal to the ambient temperature and humidity before use, and the ambient temperature and humidity should be properly controlled during the use.

● When using the product, please control the tension properly and ensure the tension uniformity.

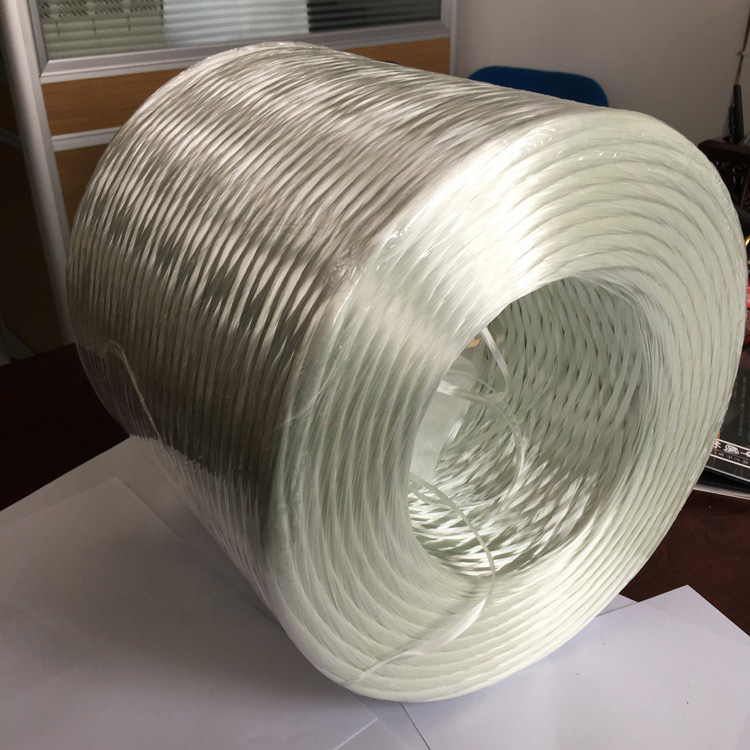

Packaging

This product is packaged with pallet + wrapping plastic film + cardboard

Storage

Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture proof area.The best temperature and humidity should be maintained at -10℃ ~35℃ and ≤80% respectively. To ensure safety and avoid damage to the product, the pallets should be stacked not more than three layers high. When the pallets are stacked in two or three layers, special care should be taken to correctly and smoothly move the upper pallet.

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for New Delivery for China 300tex-2400tex Fiberglass Roving / Direct Roving Glass Fiber Yran for Weaving, For even more data, please do not be reluctant to call us. All inquiries from you may be highly appreciated.

New Delivery for China Fiberglass Roving, Direct Roving, Strong infrastructure is the want of any organization. We’ve been backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our merchandise worldwide. To maintain smooth work flow, we’ve got sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we’re able to accomplish voluminous production without compromising on the quality.

Previous:

OEM China China Jushi Roving for Transparent Sheet Use Fiberglass Panel Roving 2400tex

Next:

High definition China Boat Molds E-Glass Fiberglass Assembled Roving SMC