We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for 7.5 Oz Fiberglass Cloth, 1708 Biaxial Fiberglass Cloth, insulation fiberglass cloth, We can customize the products according to your requirements and we can pack it for you when you order.

Manufacturer for Woven Fibreglass - High-quality Fiberglass chopped strand mat – Yaosheng Detail:

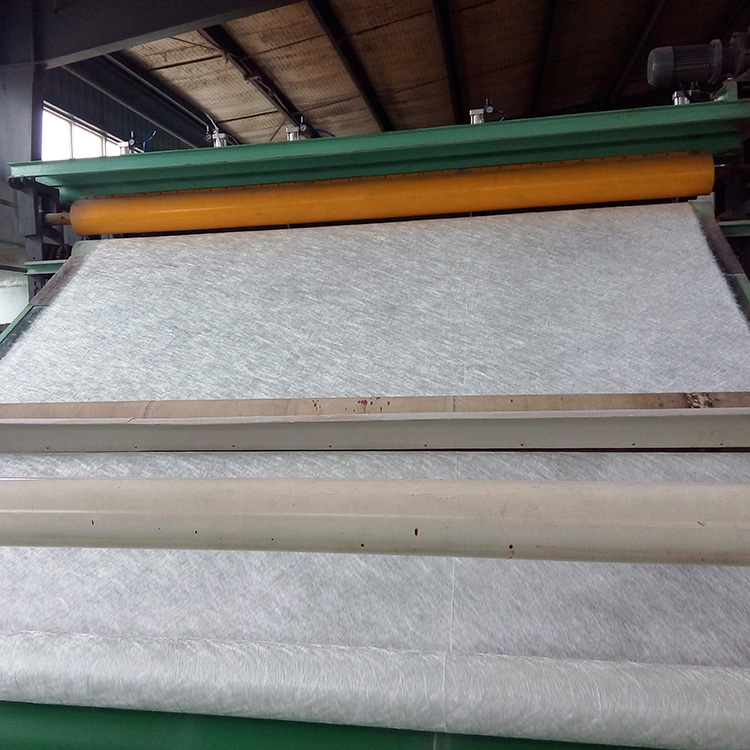

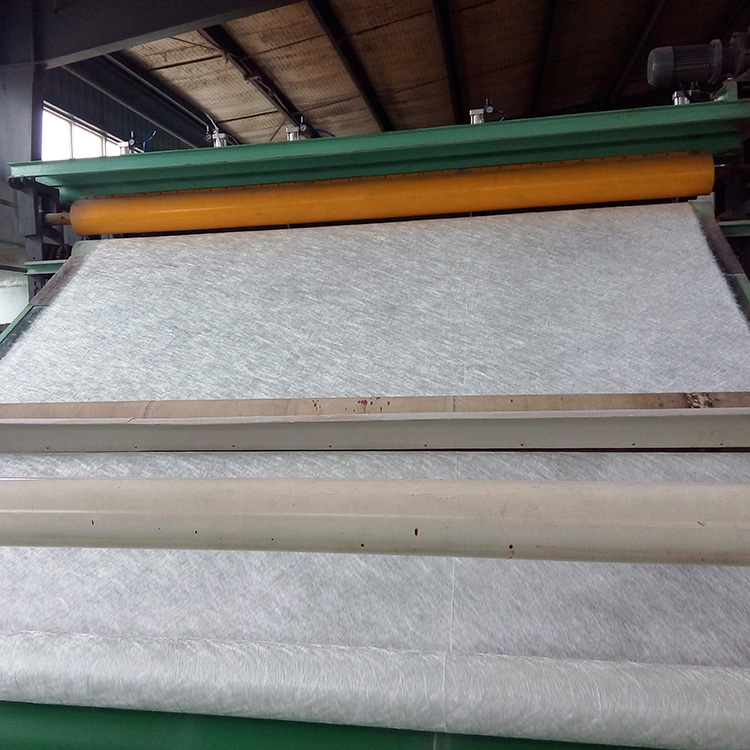

Fiberglass Mat Production Process

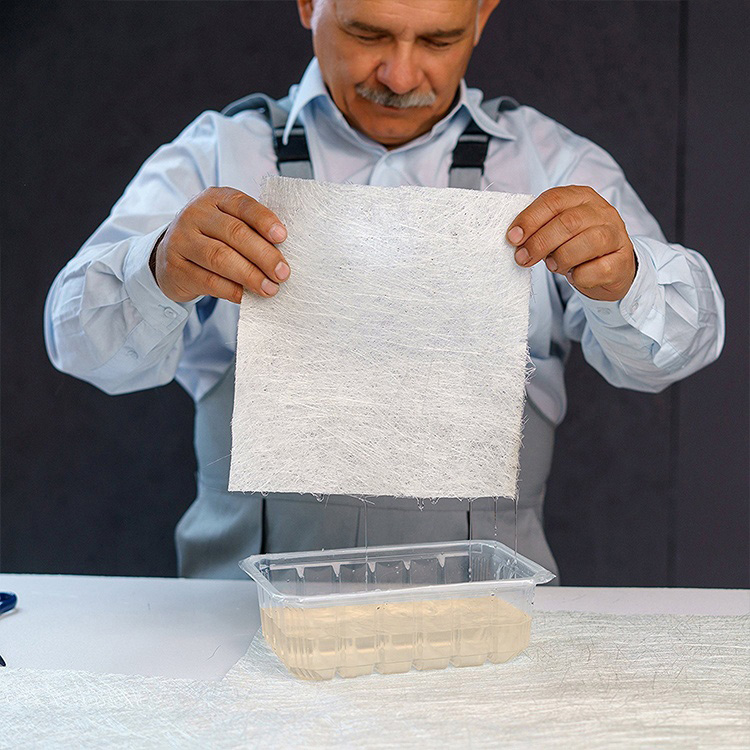

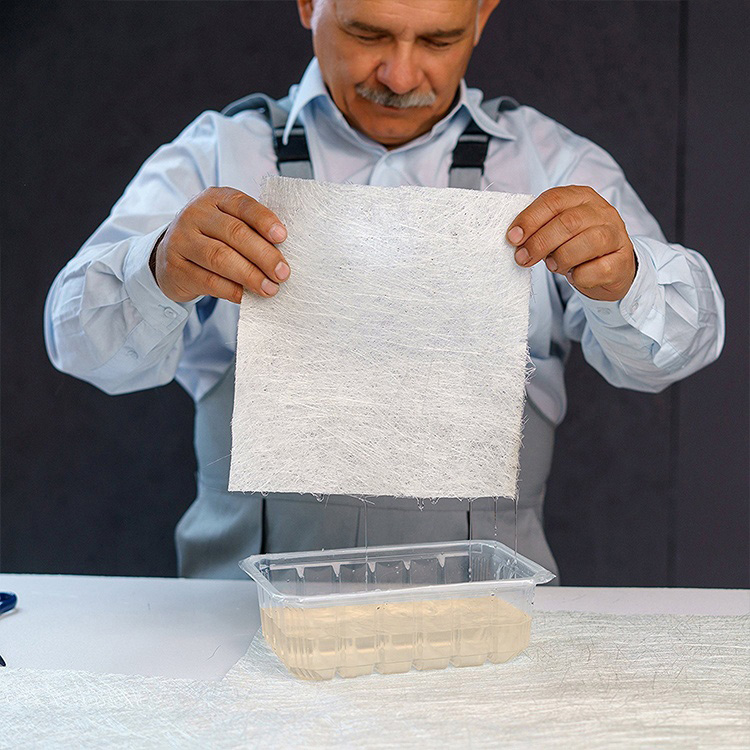

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

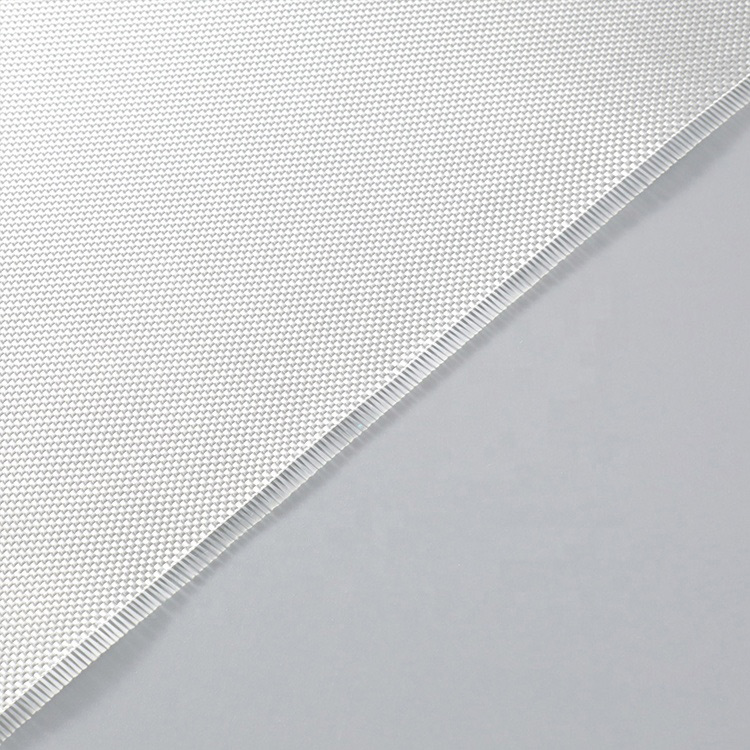

Fibreglass matting are made of randomly distributed chopped strands held together by emulsion/power binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3120mm. Special requirements may be available upon request.

Product Specifications

|

Product name

|

Type of Product

|

|

Power

|

Emulsion

|

| Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

| Fiberglass chopped strand mat |

200g |

80-100 |

2.8 – 4.8 |

≤0.1 |

200g |

70-90 |

4.2-6.2 |

≤0.2 |

| 225g |

90 -110 |

2.7 -4.7 |

≤0.1 |

225g |

75-95 |

4.1-6.1 |

≤0.2 |

| 250g |

100 – 120 |

2.6 -4.6 |

≤0.1 |

250g |

80-100 |

4.0-6.0 |

≤0.2 |

| 300g |

110-130 |

2.5-4.5 |

≤0.1 |

300g |

110-130 |

3.6-5.6 |

≤0.2 |

| 350g |

130-150 |

2.5-4.5 |

≤0.1 |

350g |

120-140 |

3.6-5.6 |

≤0.2 |

| 400g |

140-160 |

2.5-4.5 |

≤0.1 |

400g |

130-150 |

3.6-5.6 |

≤0.2 |

| 450g |

170-190 |

2.4-4.4 |

≤0.1 |

450g |

160-180 |

3.2-5.2 |

≤0.2 |

| 550g |

200-220 |

2.3-4.3 |

≤0.1 |

550g |

200-220 |

3.2-5.2 |

≤0.2 |

| 600g |

250-280 |

2.3-4.3 |

≤0.1 |

600g |

250-280 |

3.2-5.2 |

≤0.2 |

| 900g |

320-400 |

2.3-4.3 |

≤0.1 |

900g |

320-400 |

3.2-5.2 |

≤0.2 |

Product Application

The chopped strand mat are compatible with unsaturated polyester, vinyl ester and other various resins.

It’s mainly used in hand lay-up, filament winding and compression molding processes. The typical FRP products are panels, tanks, boats, complete set of sanitary equipment, automotive parts, cooling towers, pipes etc.

Product detail pictures:

Related Product Guide:

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Manufacturer for Woven Fibreglass - High-quality Fiberglass chopped strand mat – Yaosheng , The product will supply to all over the world, such as: Estonia, Montreal, Roman, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.