We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of E Glass Fiber Mat, 450g Chopped Strand Mat, Biaxial Fiberglass Mat, We, with open arms, invite all interested potential buyers to visit our web-site or get in touch with us immediately for further information and facts.

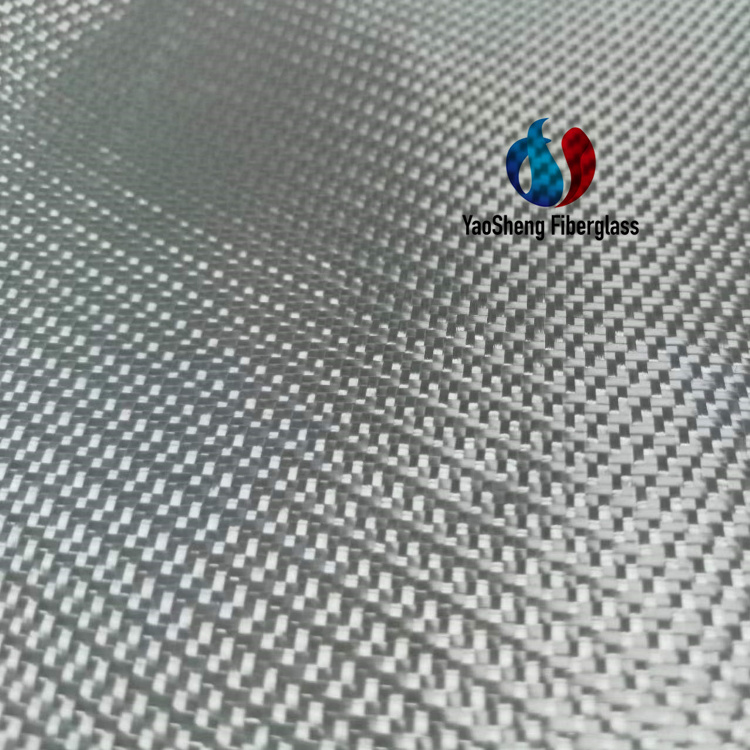

Leading Manufacturer for 1708 Fiberglass Weight - High-quality Fiberglass chopped strand mat – Yaosheng Detail:

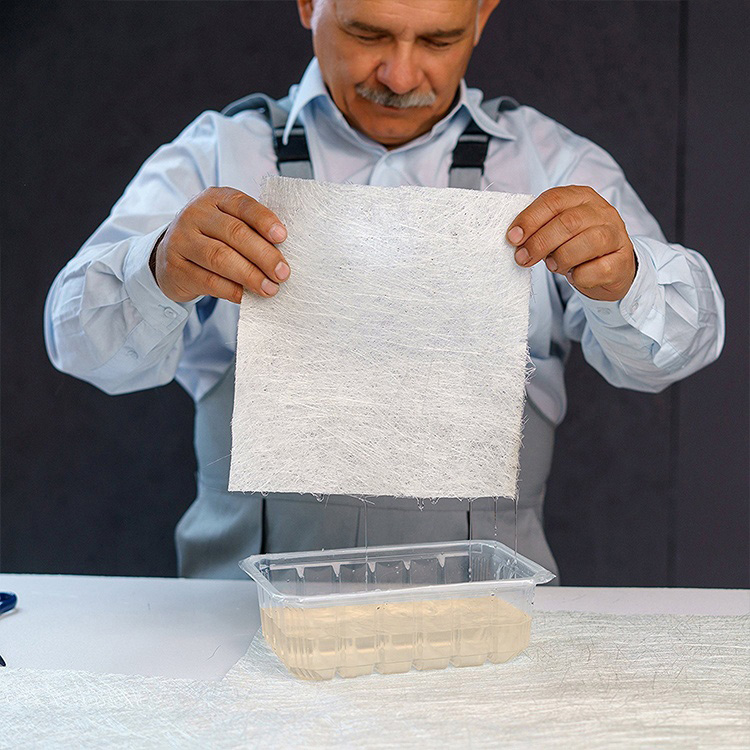

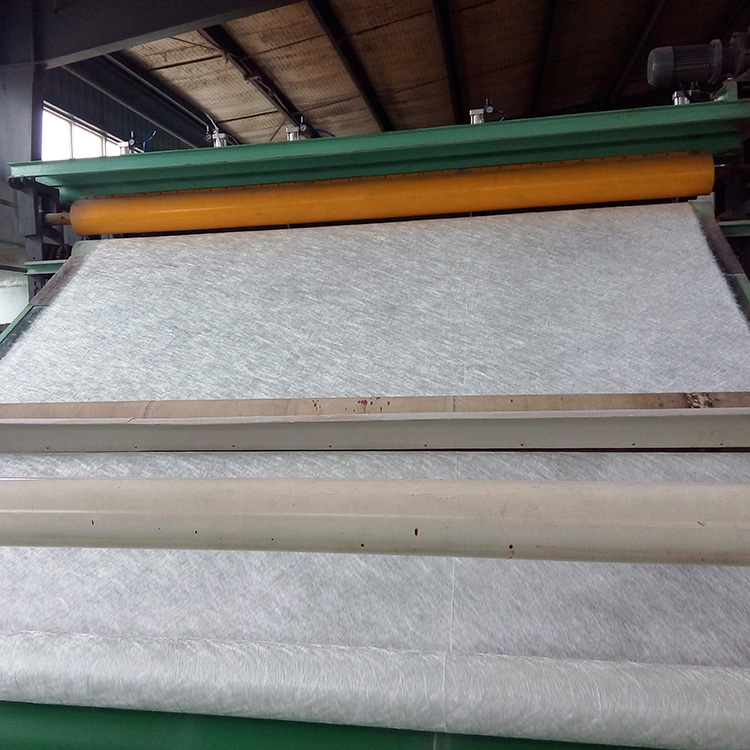

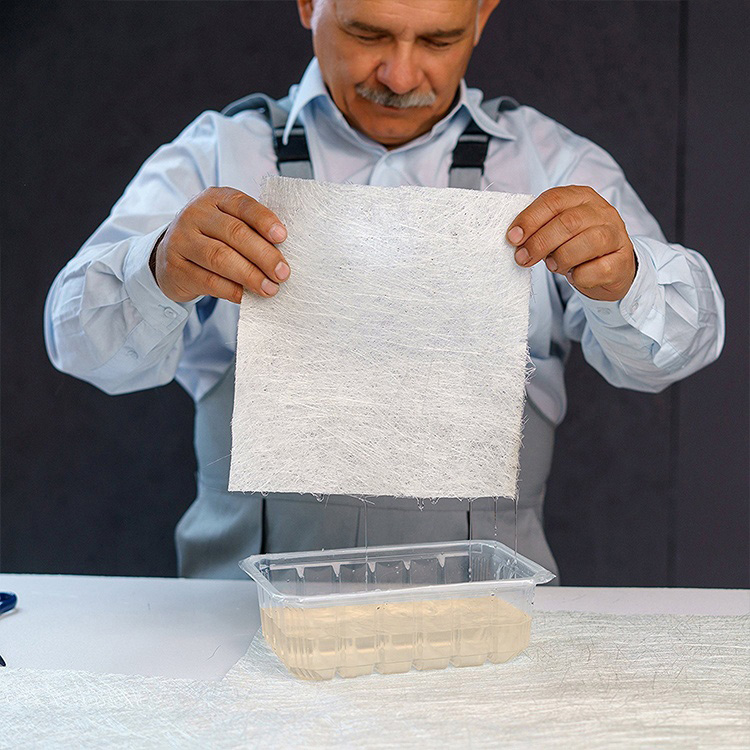

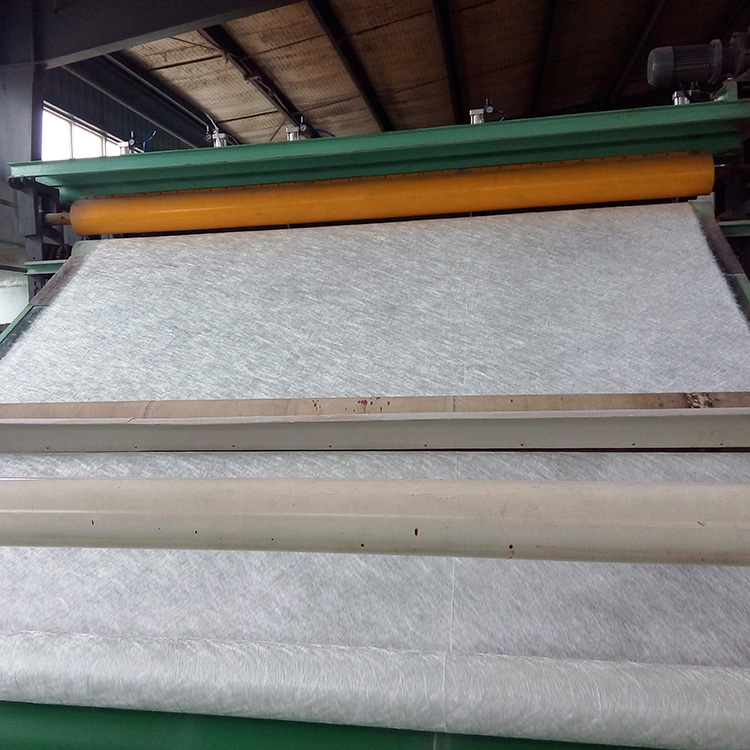

Fiberglass Mat Production Process

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

Fibreglass matting are made of randomly distributed chopped strands held together by emulsion/power binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3120mm. Special requirements may be available upon request.

Product Specifications

|

Product name

|

Type of Product

|

|

Power

|

Emulsion

|

| Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

| Fiberglass chopped strand mat |

200g |

80-100 |

2.8 – 4.8 |

≤0.1 |

200g |

70-90 |

4.2-6.2 |

≤0.2 |

| 225g |

90 -110 |

2.7 -4.7 |

≤0.1 |

225g |

75-95 |

4.1-6.1 |

≤0.2 |

| 250g |

100 – 120 |

2.6 -4.6 |

≤0.1 |

250g |

80-100 |

4.0-6.0 |

≤0.2 |

| 300g |

110-130 |

2.5-4.5 |

≤0.1 |

300g |

110-130 |

3.6-5.6 |

≤0.2 |

| 350g |

130-150 |

2.5-4.5 |

≤0.1 |

350g |

120-140 |

3.6-5.6 |

≤0.2 |

| 400g |

140-160 |

2.5-4.5 |

≤0.1 |

400g |

130-150 |

3.6-5.6 |

≤0.2 |

| 450g |

170-190 |

2.4-4.4 |

≤0.1 |

450g |

160-180 |

3.2-5.2 |

≤0.2 |

| 550g |

200-220 |

2.3-4.3 |

≤0.1 |

550g |

200-220 |

3.2-5.2 |

≤0.2 |

| 600g |

250-280 |

2.3-4.3 |

≤0.1 |

600g |

250-280 |

3.2-5.2 |

≤0.2 |

| 900g |

320-400 |

2.3-4.3 |

≤0.1 |

900g |

320-400 |

3.2-5.2 |

≤0.2 |

Product Application

The chopped strand mat are compatible with unsaturated polyester, vinyl ester and other various resins.

It’s mainly used in hand lay-up, filament winding and compression molding processes. The typical FRP products are panels, tanks, boats, complete set of sanitary equipment, automotive parts, cooling towers, pipes etc.

Product detail pictures:

Related Product Guide:

Sticking to the principle of "Super High-quality, Satisfactory service" ,We are striving to generally be a very good business partner of you for Leading Manufacturer for 1708 Fiberglass Weight - High-quality Fiberglass chopped strand mat – Yaosheng , The product will supply to all over the world, such as: Poland, Turin, Turkey, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.