Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for glass fiber stitched mat, Core Mat Fiberglass, Fiberglass Strand Mat, Our company quickly grew in size and reputation because of its absolute dedication to high quality manufacturing, high value of products and excellent customer service.

High Quality for Glass Fibre Textiles - High-quality Fiberglass chopped strand mat – Yaosheng Detail:

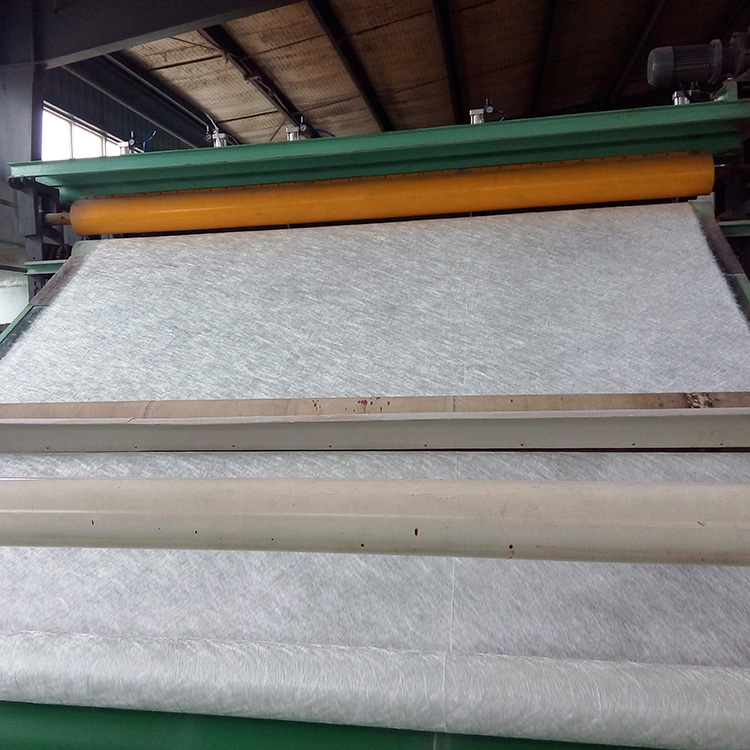

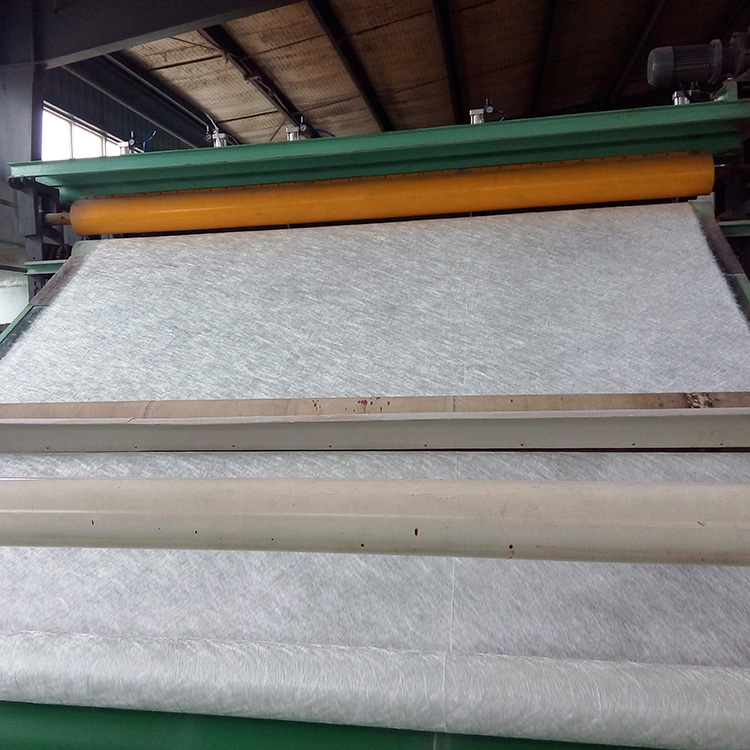

Fiberglass Mat Production Process

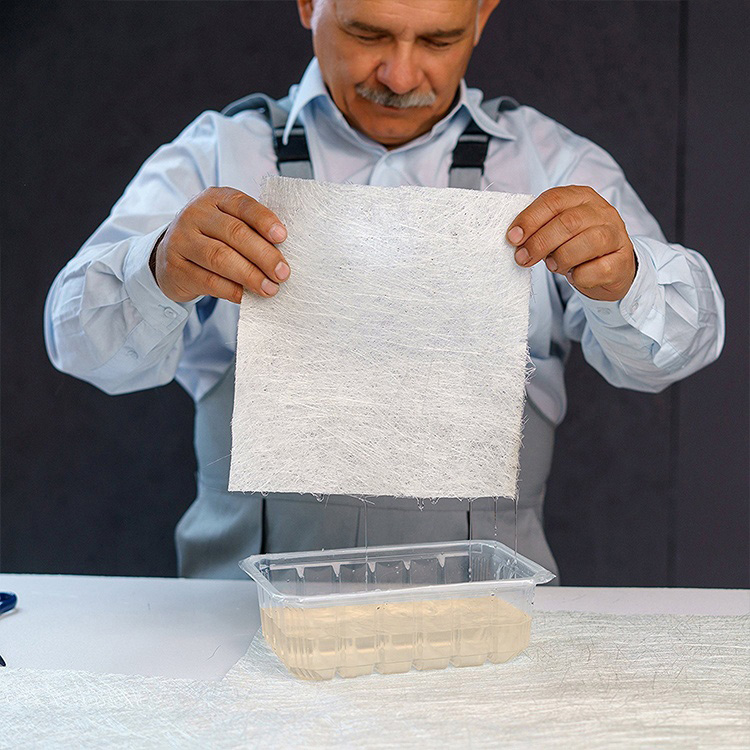

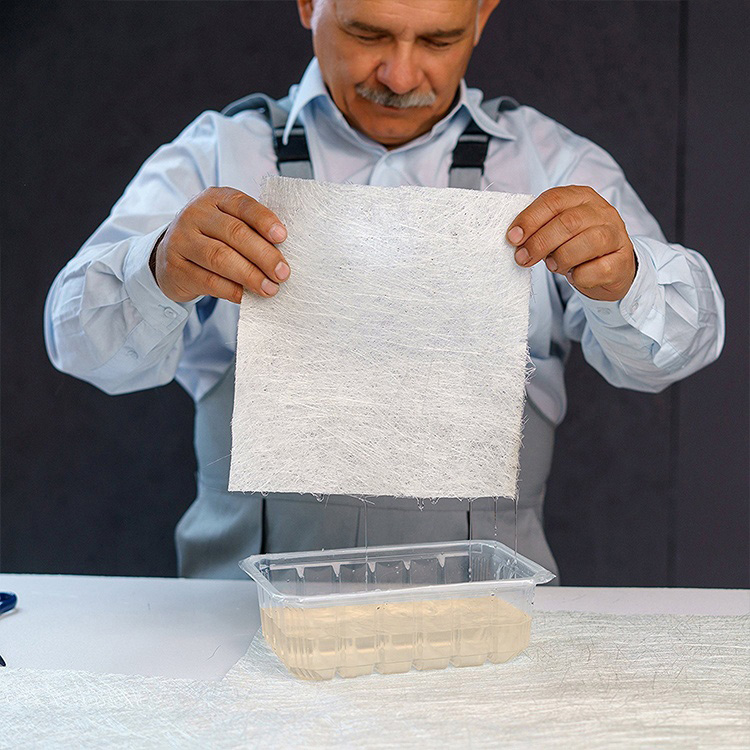

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

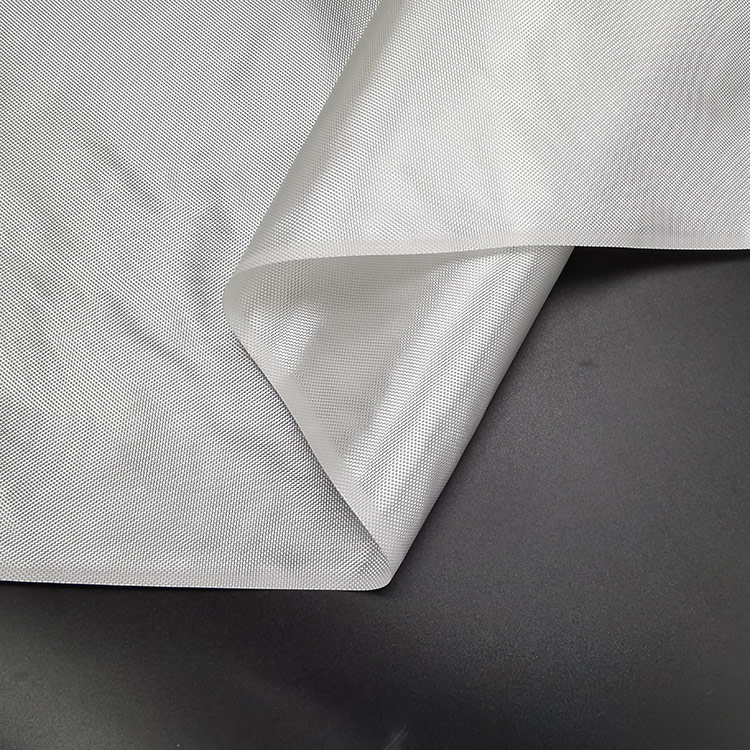

Fibreglass matting are made of randomly distributed chopped strands held together by emulsion/power binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3120mm. Special requirements may be available upon request.

Product Specifications

|

Product name

|

Type of Product

|

|

Power

|

Emulsion

|

| Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

Specs |

Tensile Strength (N) |

Loi content (%) |

Moisture (%) |

| Fiberglass chopped strand mat |

200g |

80-100 |

2.8 – 4.8 |

≤0.1 |

200g |

70-90 |

4.2-6.2 |

≤0.2 |

| 225g |

90 -110 |

2.7 -4.7 |

≤0.1 |

225g |

75-95 |

4.1-6.1 |

≤0.2 |

| 250g |

100 – 120 |

2.6 -4.6 |

≤0.1 |

250g |

80-100 |

4.0-6.0 |

≤0.2 |

| 300g |

110-130 |

2.5-4.5 |

≤0.1 |

300g |

110-130 |

3.6-5.6 |

≤0.2 |

| 350g |

130-150 |

2.5-4.5 |

≤0.1 |

350g |

120-140 |

3.6-5.6 |

≤0.2 |

| 400g |

140-160 |

2.5-4.5 |

≤0.1 |

400g |

130-150 |

3.6-5.6 |

≤0.2 |

| 450g |

170-190 |

2.4-4.4 |

≤0.1 |

450g |

160-180 |

3.2-5.2 |

≤0.2 |

| 550g |

200-220 |

2.3-4.3 |

≤0.1 |

550g |

200-220 |

3.2-5.2 |

≤0.2 |

| 600g |

250-280 |

2.3-4.3 |

≤0.1 |

600g |

250-280 |

3.2-5.2 |

≤0.2 |

| 900g |

320-400 |

2.3-4.3 |

≤0.1 |

900g |

320-400 |

3.2-5.2 |

≤0.2 |

Product Application

The chopped strand mat are compatible with unsaturated polyester, vinyl ester and other various resins.

It’s mainly used in hand lay-up, filament winding and compression molding processes. The typical FRP products are panels, tanks, boats, complete set of sanitary equipment, automotive parts, cooling towers, pipes etc.

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for High Quality for Glass Fibre Textiles - High-quality Fiberglass chopped strand mat – Yaosheng , The product will supply to all over the world, such as: Dominica, Russia, Iraq, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .