“Sincerity, Innovation, Rigorousness, and Efficiency” is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Factory Selling Fiberglass Roving for Pultrusion Process, We value your inquiry, For more details, please get hold of us, we’ll reply you ASAP!

“Sincerity, Innovation, Rigorousness, and Efficiency” is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Fiberglass Roving, Pultrusion E Glass Roving, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we’ll be the market leader, please don??¥t hesitate to contact us by phone or email, if you are interested in any of our goods.

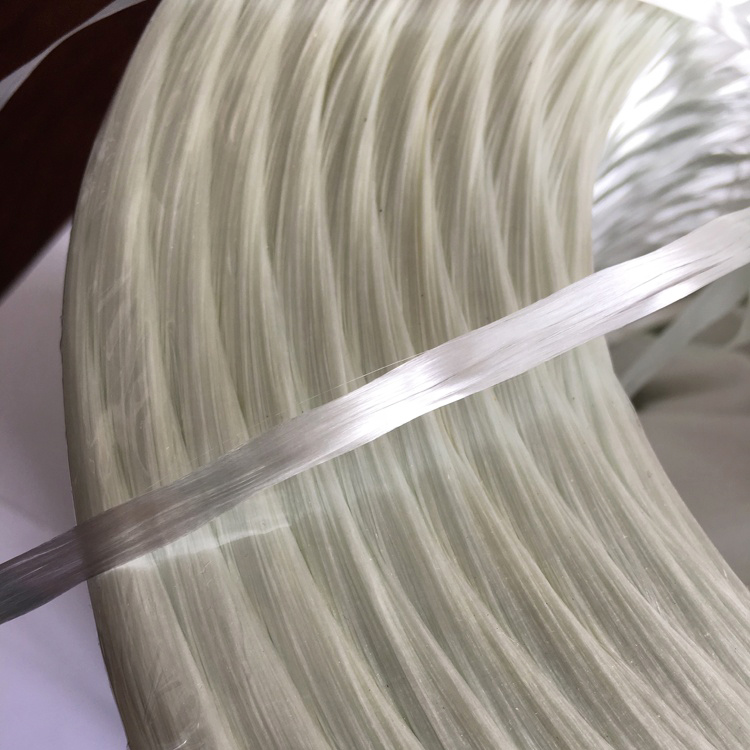

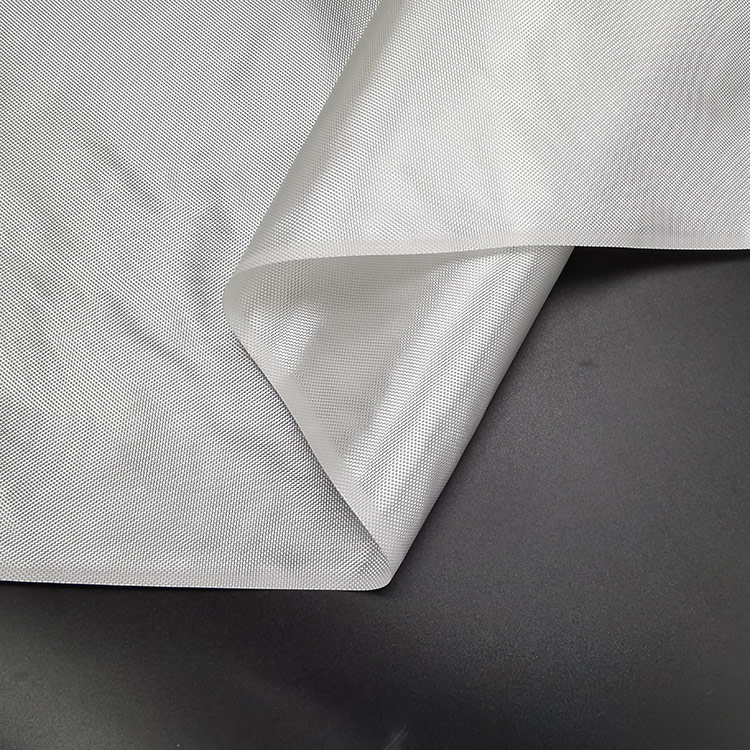

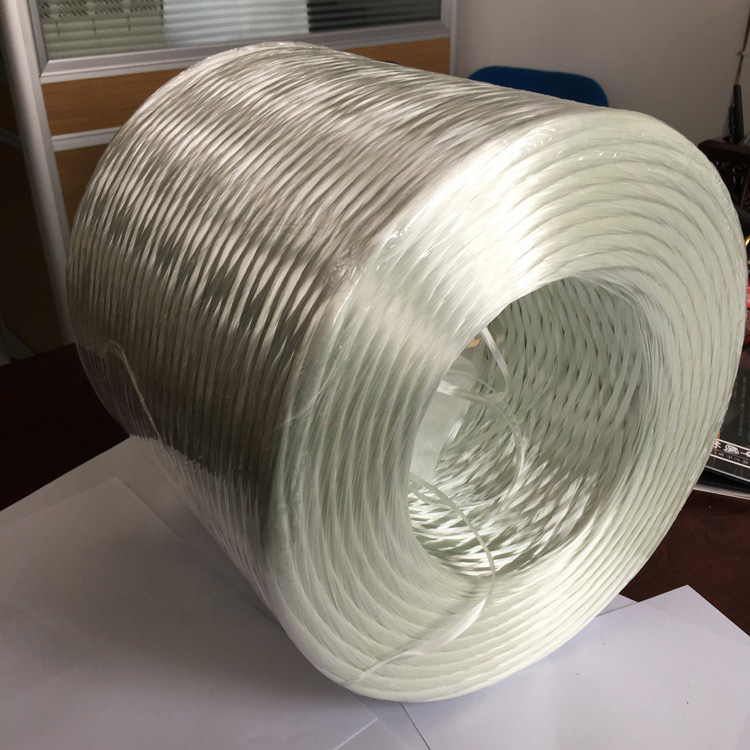

The product glass fiber roving is produced with E glass formula, which is suitable for reinforced unsaturated polyester resin, vinyl resin, epoxy resin, polyurethane resin and other thermosetting resin systems.

Has good versatility. It can be used in winding forming process, especially suitable for high-speed, high-tension pultrusion process.

Products are used in the manufacture of tent poles, outdoor travel products, pressure vessels, pipes, boats, chemical Industrial storage tanks, wind blades, geogrids, fiber optic cable reinforced cores, UHV and UHV power transmission, substation and other fields, cable trays, pultruded profiles, high-speed rail sleepers and other fields.

Specifications

| Model |

Roving type |

Glass type |

Sizing type |

Typical filament diameter (um) |

Typical linear density (tex) |

| ER-276 |

Assembled Roving

|

E

|

Silane

|

13 、16 |

2400 、4800 |

| EDR-310H |

Direct/ Assembled |

17 、24 |

1200 、2400 |

| EDR-312 |

Direct Roving |

13 、16 、24 、31 |

100、200、300、400、2400、4800 |

| EDR-312T |

17 、21 、23 、24 、31 、32 |

1200、2400、2000、4400、4800 |

| EDR-316H |

13 、17 |

300 、660 、600 、1200 |

| EDR-332 |

17 、24 、31 |

600 、1200 、2400、4800 |

| EDR-386H |

13 、17 、24、31 |

300、600、1200、2400、4800 |

| EDR-386T |

13、16、17、21、24、31 |

200、300、400、600、1200、2400、4800 |

Technical Parameters

| Model |

Moisture content(%) |

Sizing content(%) |

Breakage strength(N/tex) |

Tensile strength(MPa) |

Tensile modulus(GPa) |

Shear strength(MPa) |

Bending strength(MPa) |

Bending modulus(GPa) |

| ER-276 |

≤ 0.07

|

0.55 ± 0.15 |

≥ 0.40 |

/ |

/ |

/ |

/ |

/ |

| EDR-310H |

≤ 0.10 |

0.55 ± 0.10 |

≥ 0.40 (<4800 tex)

≥ 0.30 ( ≥ 4800 tex) |

2316 |

81.2 |

/ |

/ |

/ |

| EDR-312 |

≤ 0.10 |

0.60 ± 0.15 |

≥ 0.40 ( ≤ 4400 tex)

≥ 0.30 ( >4400 tex) |

2513 |

82.0 |

67 |

/ |

/ |

| EDR-312T |

≤ 0.10 |

0.58 ± 0.10

0.70 ± 0.15 (17600 tex) |

≥ 0.40 ( ≤ 4400 tex)

≥ 0.30 (4401~9600 tex)

≥ 0.25 ( >9600 tex) |

2265 |

81.17 |

/ |

/ |

/ |

| EDR-316H |

≤ 0.10 |

0.40 ± 0.10 |

≥ 0.40 |

2453 |

82.0 |

/ |

/ |

/ |

| EDR-332 |

≤ 0.10 |

0.45 ± 0.15 |

≥ 0.40 (<4800 tex)

≥ 0.35 ( ≥ 4800 tex) |

/ |

/ |

/ |

1400 |

50 |

| EDR-386H |

≤ 0.10 |

0.50 ± 0.15 |

≥ 0.40 (<17 um)

≥0.35 (18~24 um)

≥ 0.30 ( >24 um) |

2765 / 2682 |

81.76 / 81.47 |

/ |

/ |

/ |

| EDR-386T |

≤ 0.10 |

0.60 ± 0.10 |

≥ 0.40 ( ≤ 2400 tex)

≥ 0.35 (2401~4800 tex)

≥ 0.30 ( >4800 tex) |

2660 / 2580 |

80.22 / 80.12 |

68.0 |

/ |

/ |

Instructions

◎ It should be stored in the original packaging before use. This product is best used within 12 months.

◎ When using the product, pay attention to avoid product damage, rubbing, etc.

◎ Properly control the ambient temperature and humidity during use, and adjust the temperature and humidity of the yarn before use to balance the ambient temperature and humidity.

◎ Please control the tension reasonably and ensure the uniformity of tension when using.

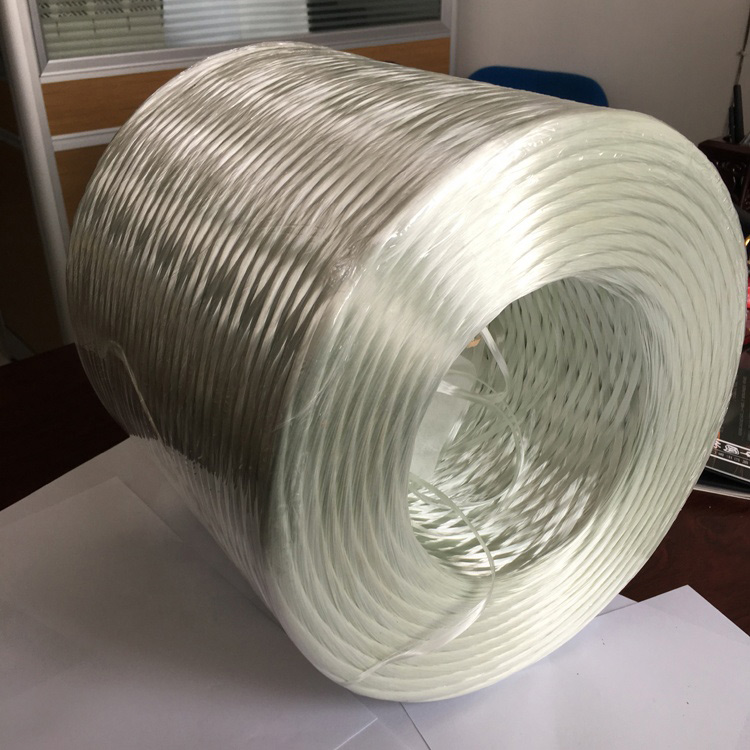

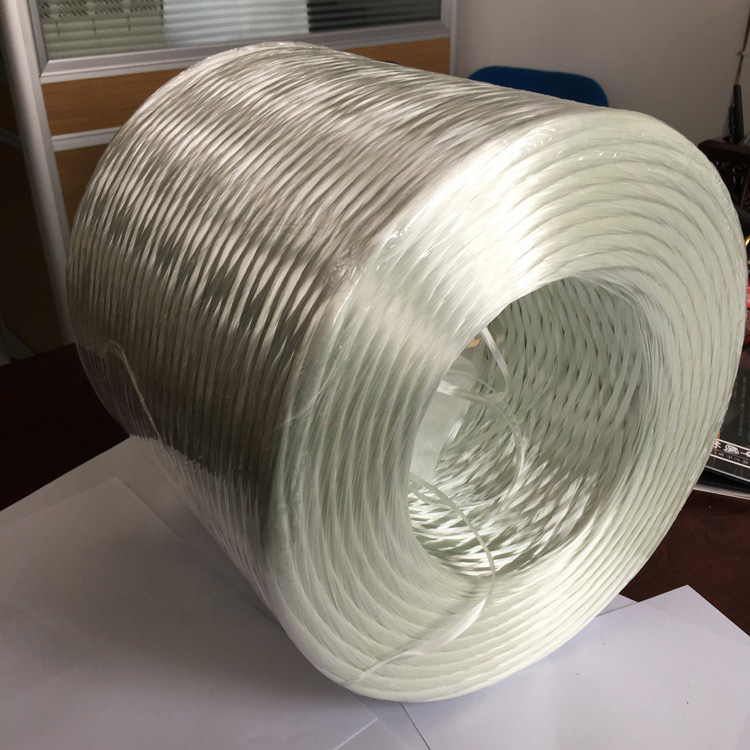

Packaging

Glass fiber roving products are packed in wooden pallets, the middle layer is separated by cardboard to prevent the product from being squeezed, and shrink film is used, and the outermost layer is packed with stretch film.

Storage

The best storage conditions for this product are -10℃~35℃, relative humidity ≤80%. To ensure safety, product pallets should not be stacked more than three layers. Please move the upper pallets correctly and smoothly when stacking.”Sincerity, Innovation, Rigorousness, and Efficiency” is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Factory Selling China Fiberglass Roving for Pultrusion Process, We value your inquiry, For more details, please get hold of us, we’ll reply you ASAP!

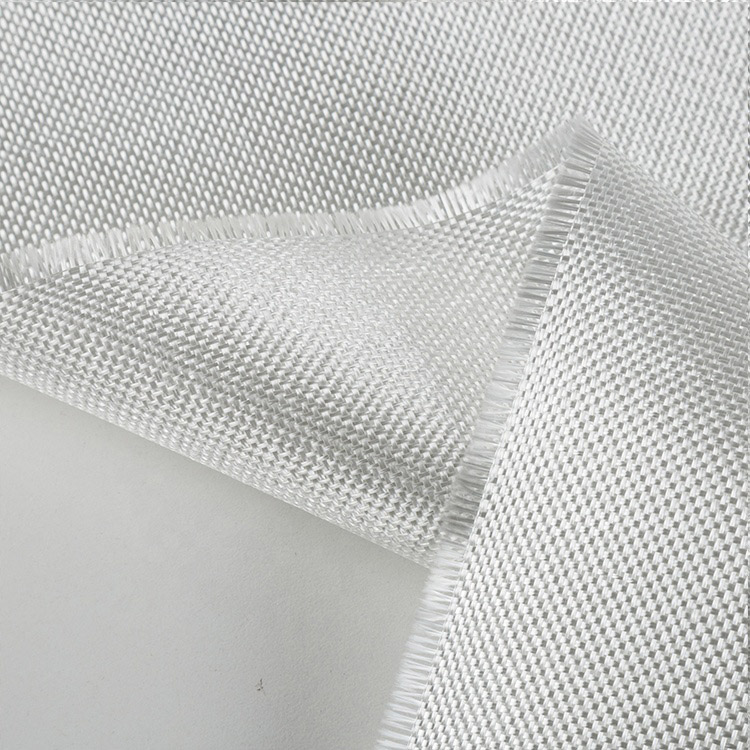

Factory Selling China Fiberglass Roving, Chopped Strand Mat, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we’ll be the market leader, please don??¥t hesitate to contact us by phone or email, if you are interested in any of our goods.

Previous:

High Quality for China Hot Sale 2400tex E-Glass Direct Roving

Next:

Wholesale Discount China Excellent Dispersion Superior Transparency Fiberglass Roving for Panel