Our pursuit and firm aim should be to “Always fulfill our buyer requirements”. We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for 900tex 1200tex 2400tex Thermoplastic Pultrusion Roving for Injection Molding, Since the manufacturing facility founded, we have now committed on the progress of new products. While using the social and economic pace, we are going to continue to carry forward the spirit of “high high-quality, efficiency, innovation, integrity”, and persist with the operating principle of “credit to start with, customer initially, top quality excellent”. We’ll make a amazing long run in hair output with our companions.

Our pursuit and firm aim should be to “Always fulfill our buyer requirements”. We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for China Fiberglass Molding Roving, Fiberglass Injection Roving, In order to meet our market demands, we have now paied more attention to the quality of our goods and services. Now we can meet customers’ special requirements for special designs. We persistently develop our enterprise spirit “quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

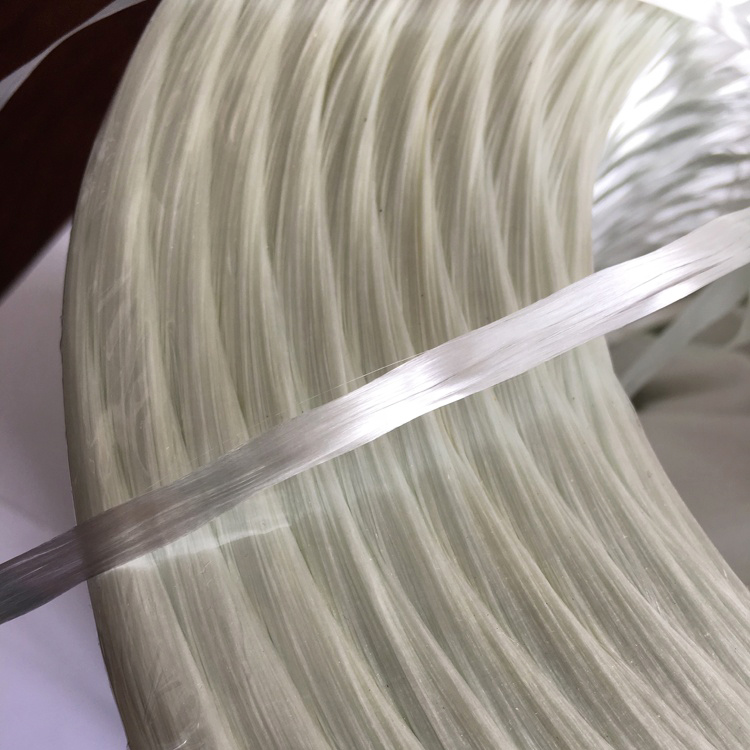

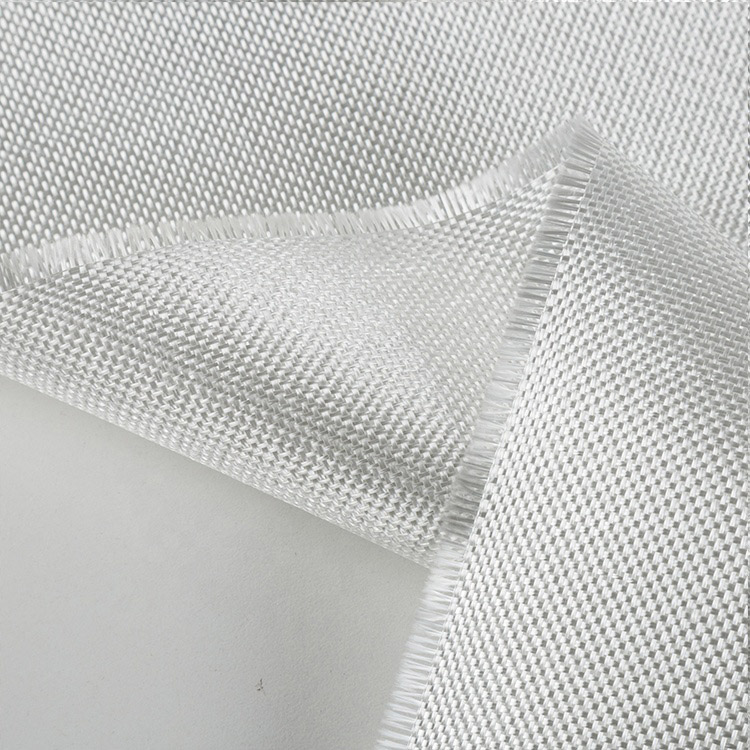

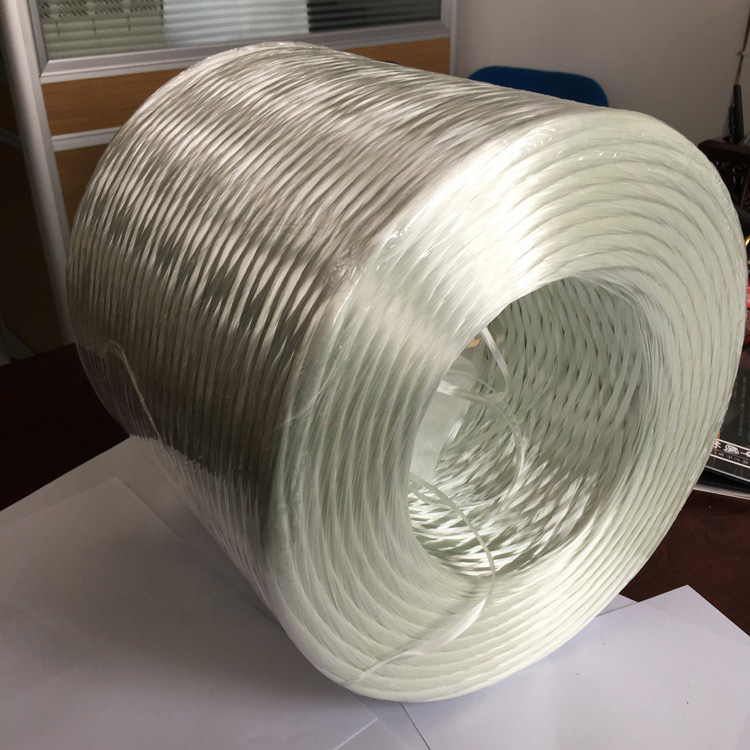

The product glass fiber roving is produced with E glass formula, which is suitable for reinforced unsaturated polyester resin, vinyl resin, epoxy resin, polyurethane resin and other thermosetting resin systems.

Has good versatility. It can be used in winding forming process, especially suitable for high-speed, high-tension pultrusion process.

Products are used in the manufacture of tent poles, outdoor travel products, pressure vessels, pipes, boats, chemical Industrial storage tanks, wind blades, geogrids, fiber optic cable reinforced cores, UHV and UHV power transmission, substation and other fields, cable trays, pultruded profiles, high-speed rail sleepers and other fields.

Specifications

| Model |

Roving type |

Glass type |

Sizing type |

Typical filament diameter (um) |

Typical linear density (tex) |

| ER-276 |

Assembled Roving

|

E

|

Silane

|

13 、16 |

2400 、4800 |

| EDR-310H |

Direct/ Assembled |

17 、24 |

1200 、2400 |

| EDR-312 |

Direct Roving |

13 、16 、24 、31 |

100、200、300、400、2400、4800 |

| EDR-312T |

17 、21 、23 、24 、31 、32 |

1200、2400、2000、4400、4800 |

| EDR-316H |

13 、17 |

300 、660 、600 、1200 |

| EDR-332 |

17 、24 、31 |

600 、1200 、2400、4800 |

| EDR-386H |

13 、17 、24、31 |

300、600、1200、2400、4800 |

| EDR-386T |

13、16、17、21、24、31 |

200、300、400、600、1200、2400、4800 |

Technical Parameters

| Model |

Moisture content(%) |

Sizing content(%) |

Breakage strength(N/tex) |

Tensile strength(MPa) |

Tensile modulus(GPa) |

Shear strength(MPa) |

Bending strength(MPa) |

Bending modulus(GPa) |

| ER-276 |

≤ 0.07

|

0.55 ± 0.15 |

≥ 0.40 |

/ |

/ |

/ |

/ |

/ |

| EDR-310H |

≤ 0.10 |

0.55 ± 0.10 |

≥ 0.40 (<4800 tex)

≥ 0.30 ( ≥ 4800 tex) |

2316 |

81.2 |

/ |

/ |

/ |

| EDR-312 |

≤ 0.10 |

0.60 ± 0.15 |

≥ 0.40 ( ≤ 4400 tex)

≥ 0.30 ( >4400 tex) |

2513 |

82.0 |

67 |

/ |

/ |

| EDR-312T |

≤ 0.10 |

0.58 ± 0.10

0.70 ± 0.15 (17600 tex) |

≥ 0.40 ( ≤ 4400 tex)

≥ 0.30 (4401~9600 tex)

≥ 0.25 ( >9600 tex) |

2265 |

81.17 |

/ |

/ |

/ |

| EDR-316H |

≤ 0.10 |

0.40 ± 0.10 |

≥ 0.40 |

2453 |

82.0 |

/ |

/ |

/ |

| EDR-332 |

≤ 0.10 |

0.45 ± 0.15 |

≥ 0.40 (<4800 tex)

≥ 0.35 ( ≥ 4800 tex) |

/ |

/ |

/ |

1400 |

50 |

| EDR-386H |

≤ 0.10 |

0.50 ± 0.15 |

≥ 0.40 (<17 um)

≥0.35 (18~24 um)

≥ 0.30 ( >24 um) |

2765 / 2682 |

81.76 / 81.47 |

/ |

/ |

/ |

| EDR-386T |

≤ 0.10 |

0.60 ± 0.10 |

≥ 0.40 ( ≤ 2400 tex)

≥ 0.35 (2401~4800 tex)

≥ 0.30 ( >4800 tex) |

2660 / 2580 |

80.22 / 80.12 |

68.0 |

/ |

/ |

Instructions

◎ It should be stored in the original packaging before use. This product is best used within 12 months.

◎ When using the product, pay attention to avoid product damage, rubbing, etc.

◎ Properly control the ambient temperature and humidity during use, and adjust the temperature and humidity of the yarn before use to balance the ambient temperature and humidity.

◎ Please control the tension reasonably and ensure the uniformity of tension when using.

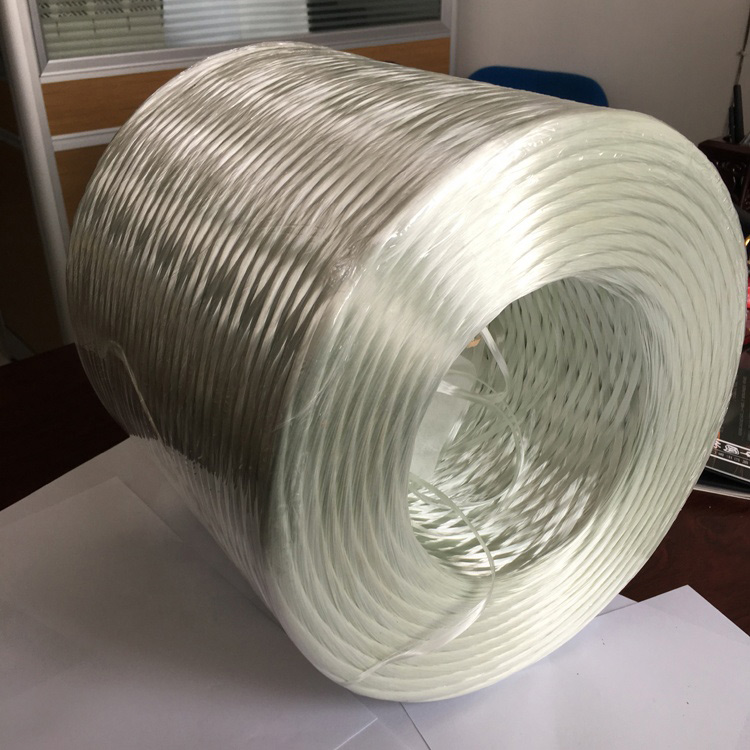

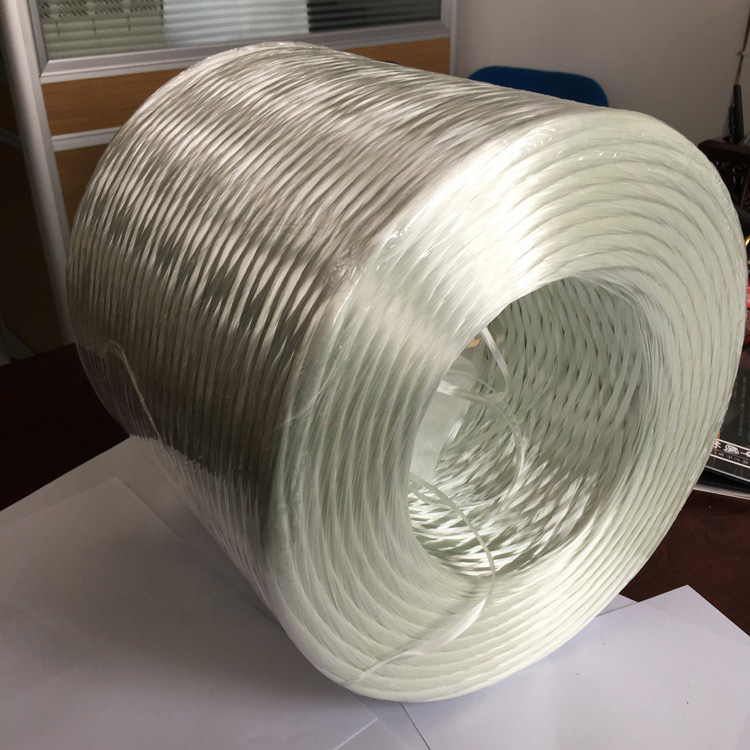

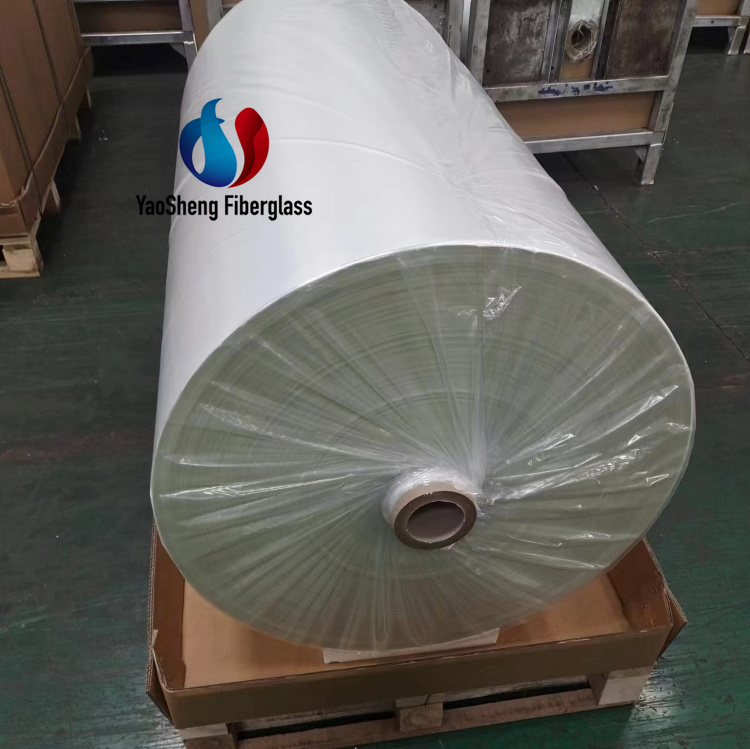

Packaging

Glass fiber roving products are packed in wooden pallets, the middle layer is separated by cardboard to prevent the product from being squeezed, and shrink film is used, and the outermost layer is packed with stretch film.

Storage

The best storage conditions for this product are -10℃~35℃, relative humidity ≤80%. To ensure safety, product pallets should not be stacked more than three layers. Please move the upper pallets correctly and smoothly when stacking.Our pursuit and firm aim should be to “Always fulfill our buyer requirements”. We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Trending Products 900tex 1200tex 2400tex Fiberglass Roving / Glass Fiber Roving / Thermoplastic Pultrusion Roving for Injection Molding, Since the manufacturing facility founded, we have now committed on the progress of new products. While using the social and economic pace, we are going to continue to carry forward the spirit of “high high-quality, efficiency, innovation, integrity”, and persist with the operating principle of “credit to start with, customer initially, top quality excellent”. We’ll make a amazing long run in hair output with our companions.

Trending Products China Fiberglass Molding Roving, Fiberglass Injection Roving, In order to meet our market demands, we have now paied more attention to the quality of our goods and services. Now we can meet customers’ special requirements for special designs. We persistently develop our enterprise spirit “quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

Previous:

Manufacturer for ECR Fiber Glass Roving Outward Unwound 1200tex

Next:

Factory 2400tex 4800tex Pultrusion Fiberglass Roving / Glass Fiber Roving