It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for Emulsion Bound Chopped Strand Mat, 1700 Fiberglass Cloth, Glass Fibre Weave, Since the factory founded, we have committed to the development of new products. With the social and economic pace, we will continue to carry forward the spirit of "high quality, efficiency, innovation, integrity", and stick to the operating principle of "credit first, customer first, quality excellent". We will create a brilliant future in hair production with our partners.

2022 New Style End To End Fiberglass Smc Roving - Fiberglass direct roving for weaving – Yaosheng Detail:

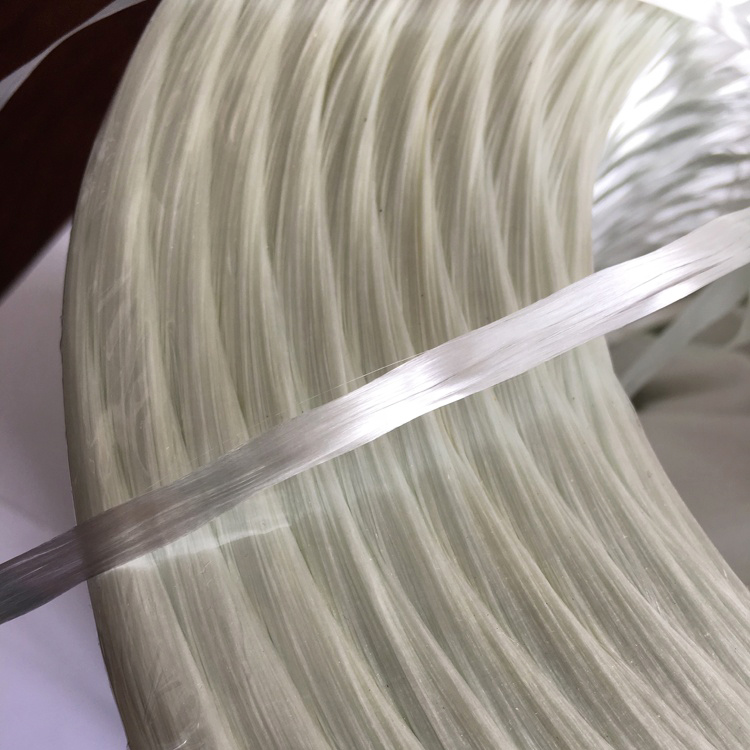

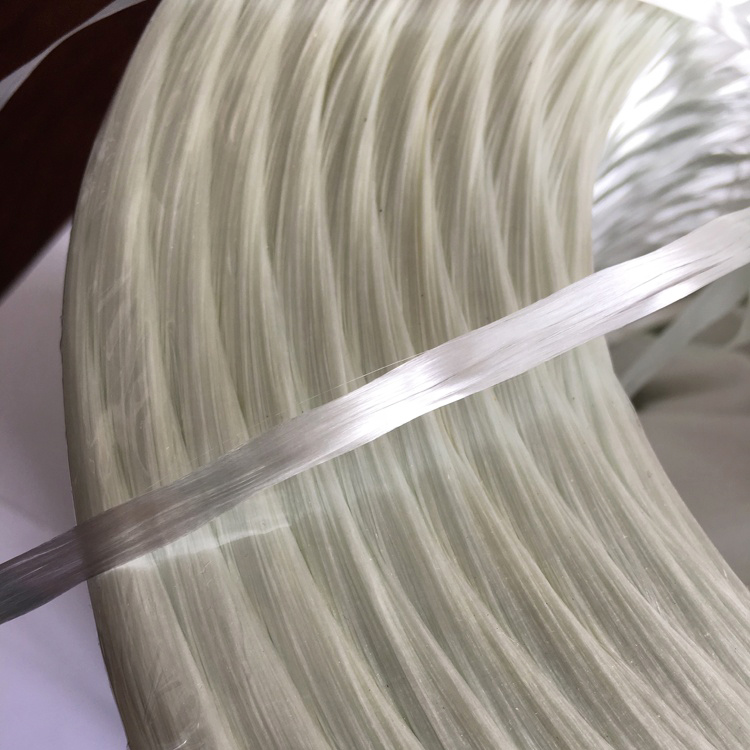

This product is an alkali-free continuous single-strand direct roving, and the surface is coated with silane-based sizing agent. It is suitable for reinforcing unsaturated polyester resin, vinyl resin, epoxy resin and polyurethane resin. It can be used for winding, pultrusion, weaving, etc. application process.

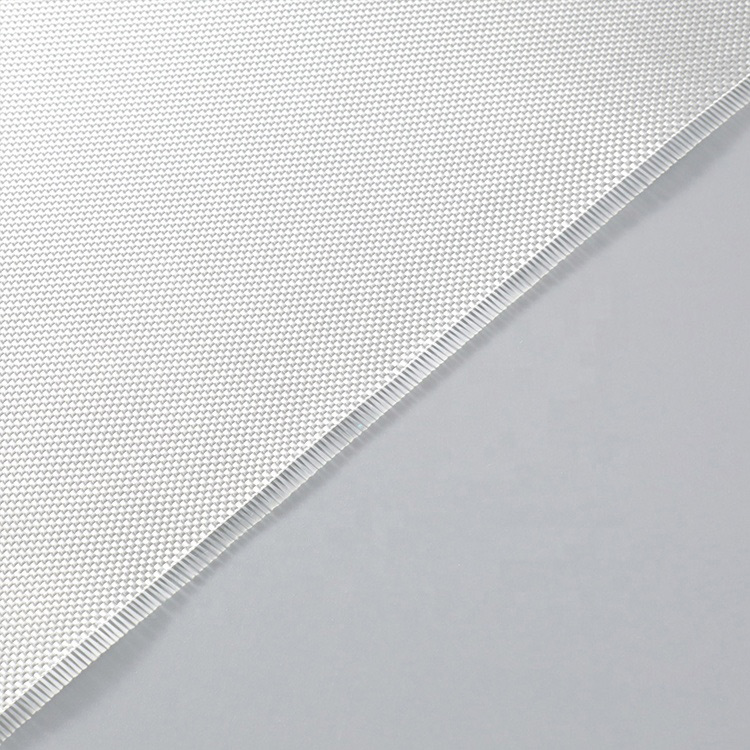

The products are suitable for manufacturing FRP pipes, pressure vessels, profiles, and fabrics for manufacturing ships, chemical storage tanks, geogrids, etc. It is also suitable for the production of cables and reinforced core materials of optical cables by pultrusion process, the manufacture of large wind power blades and yachts by vacuum-assisted resin infusion molding process, and the production of utility poles, container door panels and other products by winding or pultrusion process.

Specifications

| Model |

Glass type |

Sizing type |

Typical filament diameter (um) |

Typical linear density (tex) |

| EDR-312 |

E

|

Silane

|

13 、16 、24、 31 |

100、200、300、400、2400、4800 |

| EDR-302 |

22 、24 |

2200、4400、2400、4800 |

| EDR-306A |

17、20、21、24 |

1200、1500、1700、2400、4800 |

| EDR-320 |

17、20、22、24 |

600、1200、2400 |

| EDR-380 |

13、16、17、24 |

300、200、4800、600、1200、2400 |

| EDR-386H |

13、17、24、31 |

300、600、1200、2400、2400、4800、9600 |

| EDR-386T |

13 、16 、17 、21 、24 、31 |

200、300、400、600、1200、2400、4800 |

| EDR-390 |

13 、16、 17、 24 |

100、300、200、600、1200、1530、2400、4800 |

| EDR-396 |

13/14 、17 |

300、600、1200、2400 |

| EDR-398 |

17 |

600 、1200 、2400 |

Technical Parameters

| Model |

Moisture content(%) |

Sizing content(%) |

Breakage strength(N/tex) |

Tensile strength(MPa) |

Tensile modulus(GPa) |

Shear strength(MPa) |

| EDR-312 |

≤ 0.10

|

0.60 ± 0.15 |

≥ 0.40 ( ≤ 4400 tex)

≥ 0.30 ( >4400 tex) |

2513 |

82.0 |

67 |

| EDR-302 |

0.50 ± 0.15 |

≥ 0.35 |

2536 |

79.13 |

/ |

| EDR-306A |

0.60 ± 0.10 |

≥ 0.40 ( ≥ 4400 tex)

≥0.45 (1700~4399 tex)

≥ 0.50 ( <1700 tex) |

2732 / 2657 |

80.1 / 81.1 |

67.0 |

| EDR-320 |

0.45 ~ 0.70 |

≥ 0.40 |

2315.3 / 2488.4 |

82.5 / 82.8 |

/ |

| EDR-380 |

0.55 ± 0.15 |

≥ 0.40 |

2612 |

81.15 |

73.0 |

| EDR-386H |

0.50 ± 0.15 |

≥0.40 (<17 um)

≥0.35 (18~24 um)

≥ 0.30 (>24 um) |

2765 / 2682 |

81.76 / 81.47 |

/ |

| EDR-386T |

0.60 ± 0.10 |

≥0.40 (≤2400 tex)

≥0.35 (2401~4800 tex)

≥0.30 (>4800 tex) |

2660 / 2580 |

80.22 / 80.12 |

68.0 |

| EDR-390 |

0.55 ± 0.15 |

≥ 0.40 |

2595 |

81.9 |

74.0 |

| EDR-396 |

0.48 ± 0.10 |

≥ 0.40 |

2471 |

81.324 |

67 |

| EDR-398 |

0.55 ± 0.10 |

≥ 0.40 |

2540 |

81.95 |

71.0 |

Instructions

● The product is best used within 12 months after production, and should be kept in the original package before use.

● Care should be taken when using the product to prevent it from being scratched or damaged.

● The temperature and humidity of the product should be conditioned to be close or equal to the ambient temperature and humidity before use, and the ambient temperature and humidity should be properly controlled during the use.

● When using the product, please control the tension properly and ensure the tension uniformity.

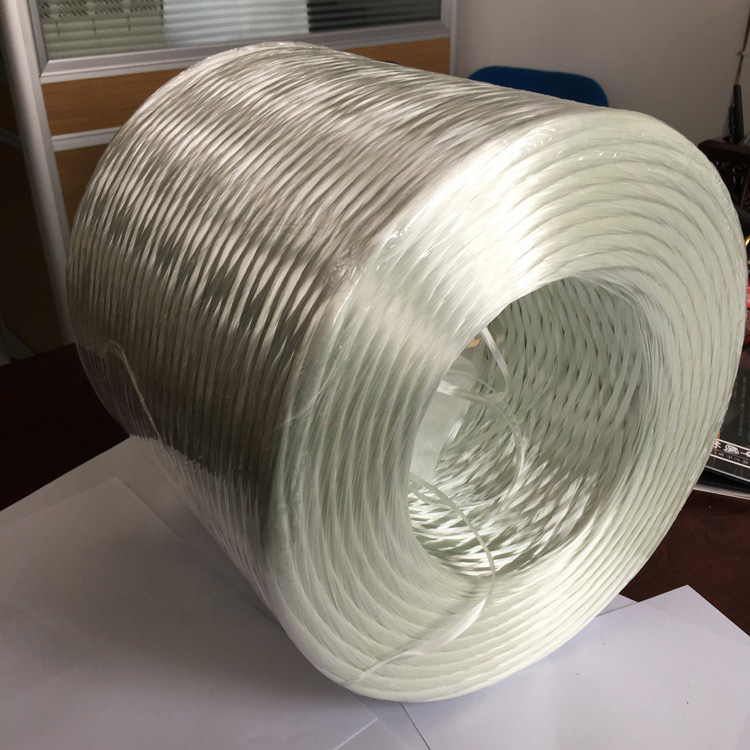

Packaging

This product is packaged with pallet + wrapping plastic film + cardboard

Storage

Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture proof area.The best temperature and humidity should be maintained at -10℃ ~35℃ and ≤80% respectively. To ensure safety and avoid damage to the product, the pallets should be stacked not more than three layers high. When the pallets are stacked in two or three layers, special care should be taken to correctly and smoothly move the upper pallet.

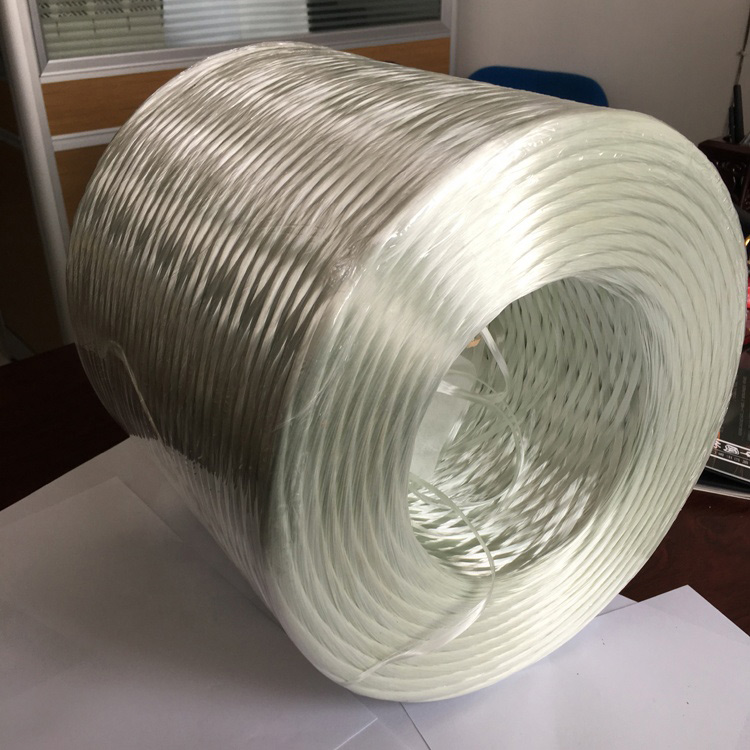

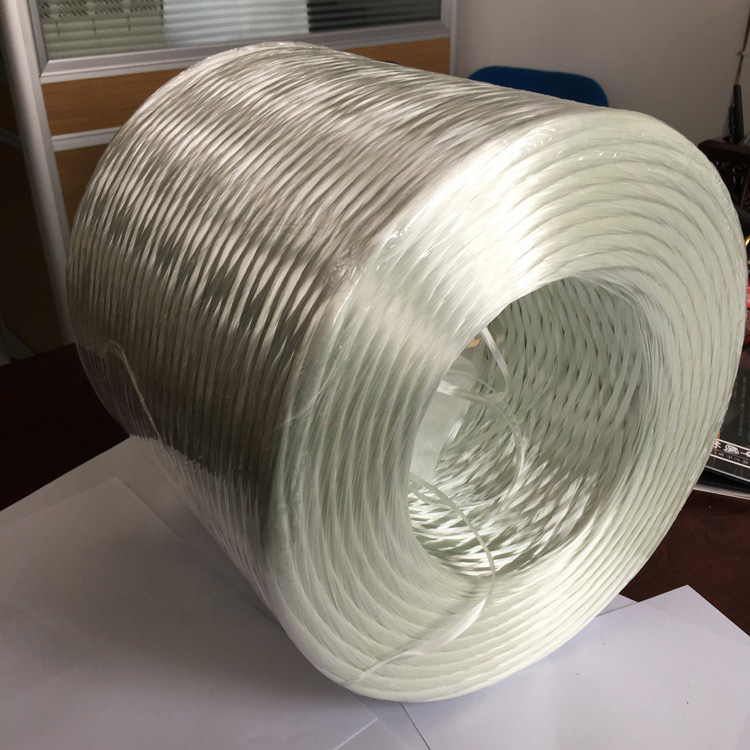

Product detail pictures:

Related Product Guide:

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for 2022 New Style End To End Fiberglass Smc Roving - Fiberglass direct roving for weaving – Yaosheng , The product will supply to all over the world, such as: Nigeria, Argentina, New Delhi, With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.